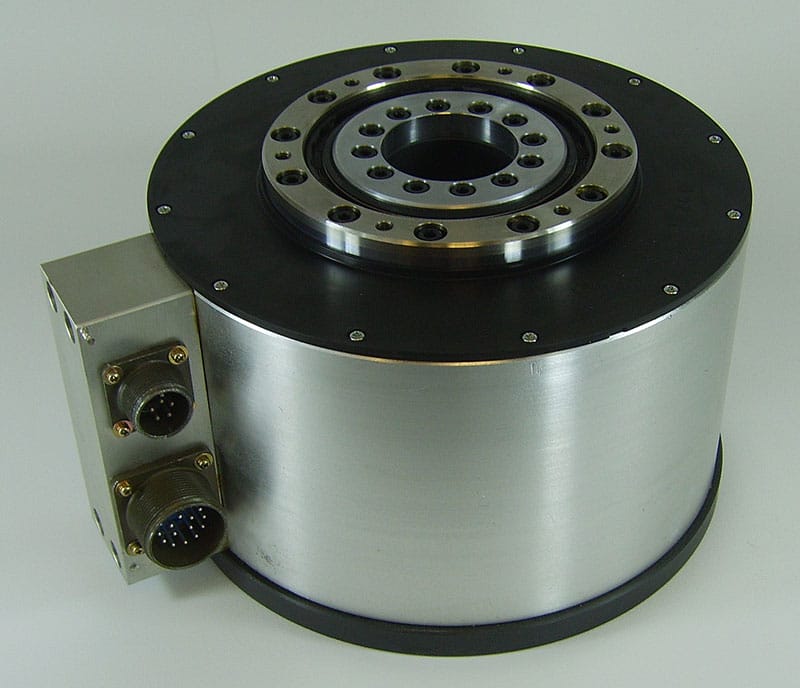

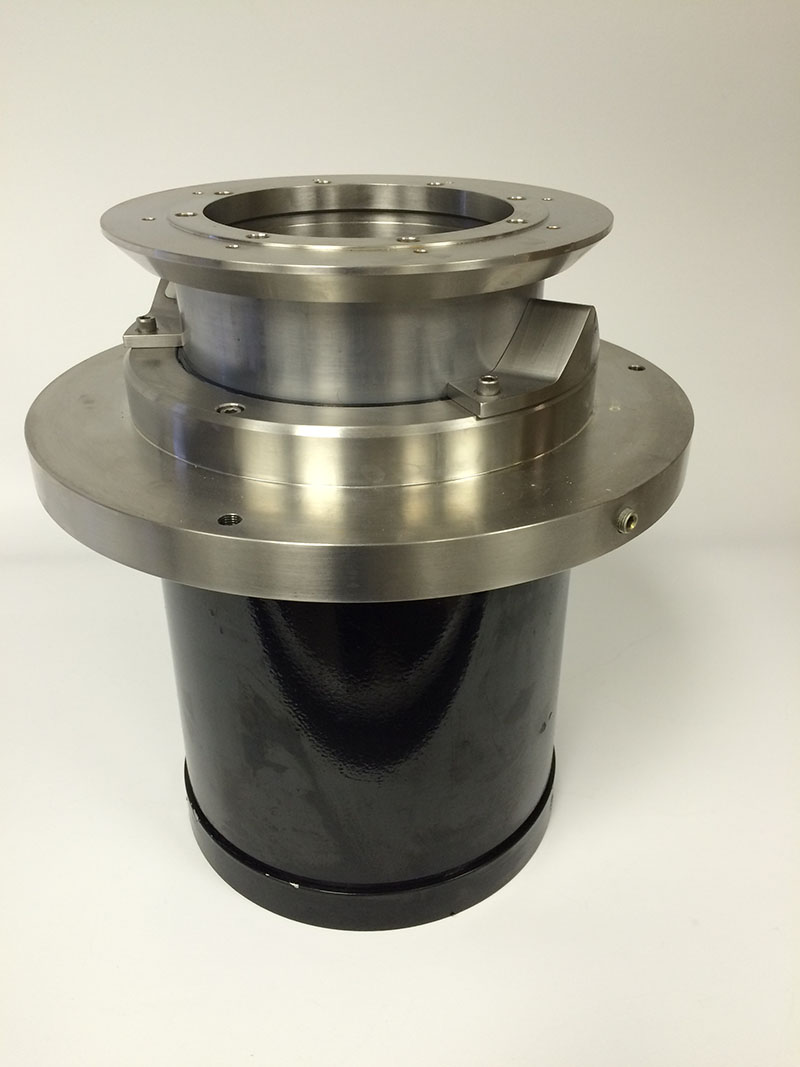

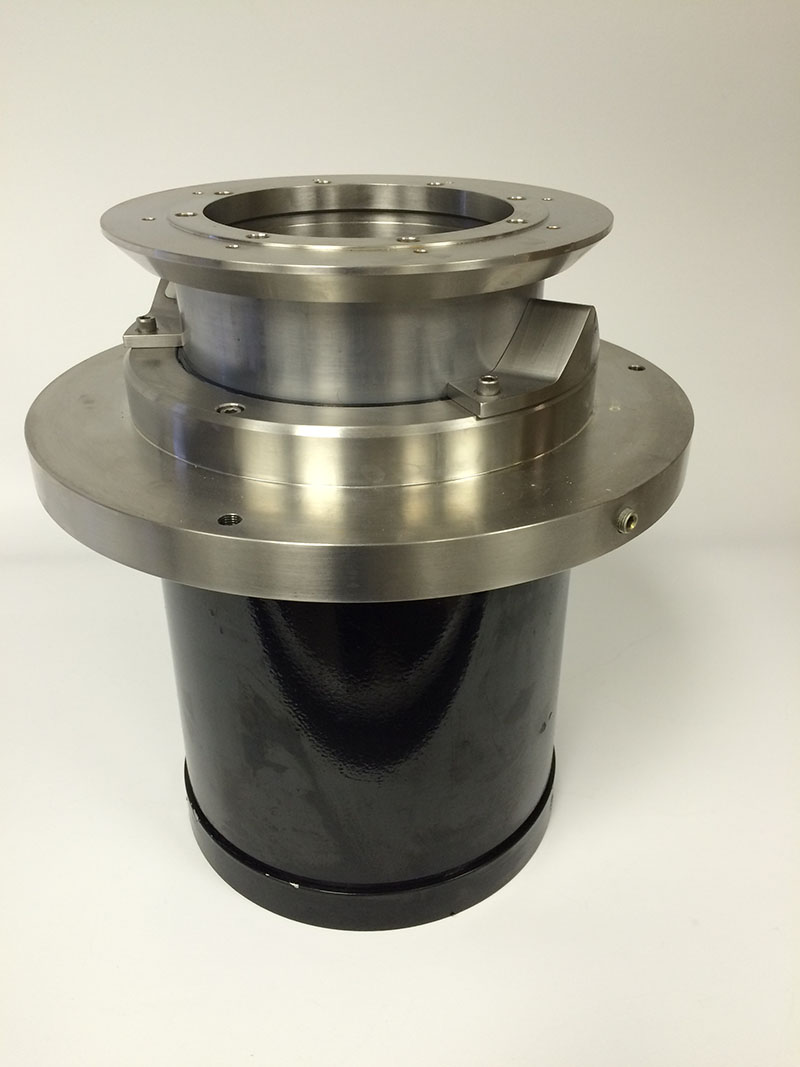

- 853-012123-001 Lam Research Harmonic Drive

- 853-012123-004 Lam Research Harmonic Drive

- 853-012175-001 Lam Research Harmonic Drive

- 853-012175-002 Lam Research Harmonic Drive

- 853-012175-003 Lam Research Harmonic Drive

- 853-012175-004 Lam Research Harmonic Drive

- 853-032776-002 Lam Research Paddle Lifter

- 853-032776-605 Lam Research Paddle Lifter

- 853-021924-003 Lam Research Paddle Lifter

- 853-032776-001 Lam Research Paddle Lifter

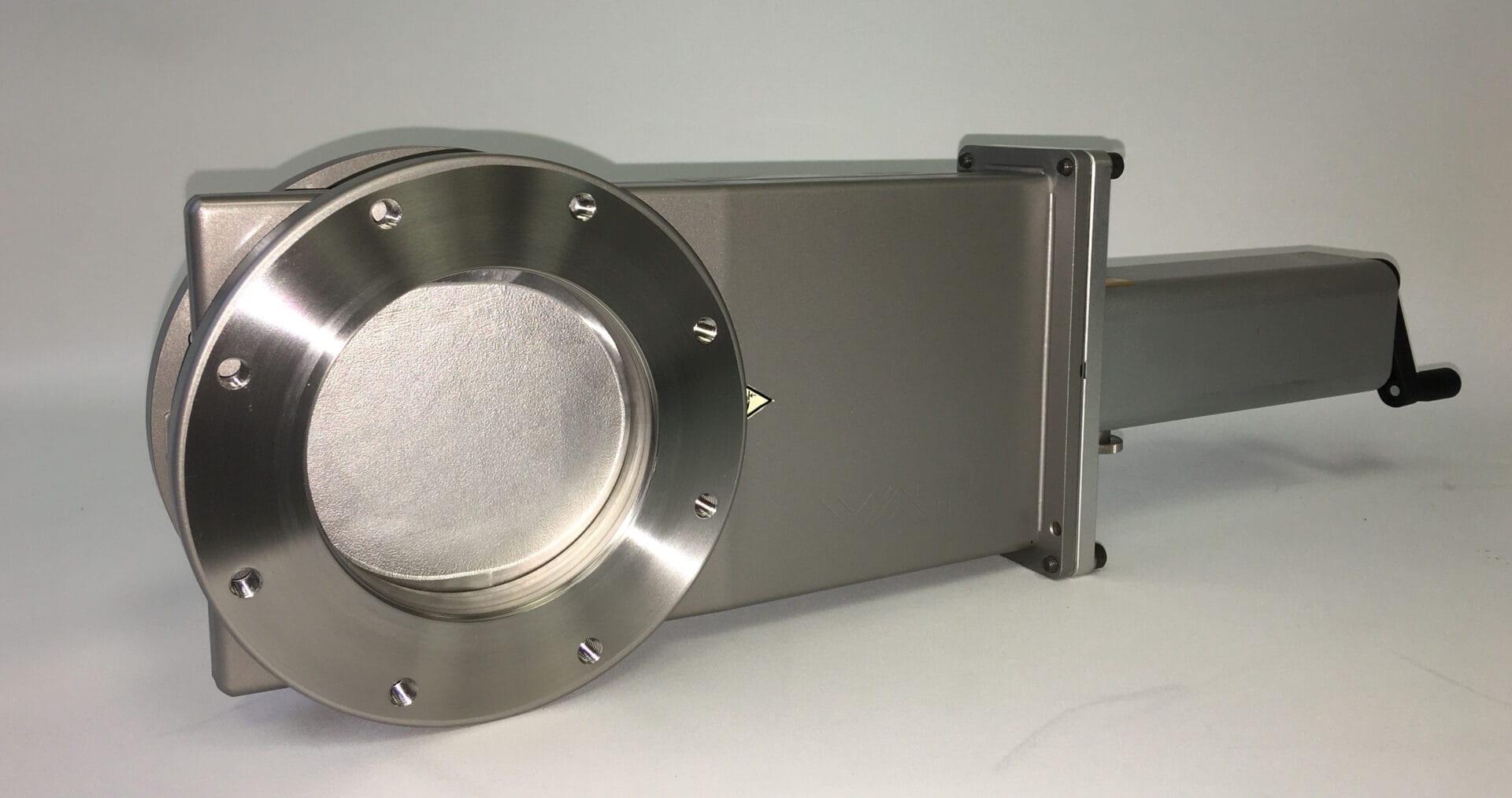

- 853-001198-002 AutoEtch Inner Gate Assembly

- 853-001198-001 AutoEtch Outer Gate Assembly

- PTS03001UNIV Varian-Agilent TriScroll 300 Pump

- PTS06001UNIV Varian-Agilent TriScroll 600 Pump

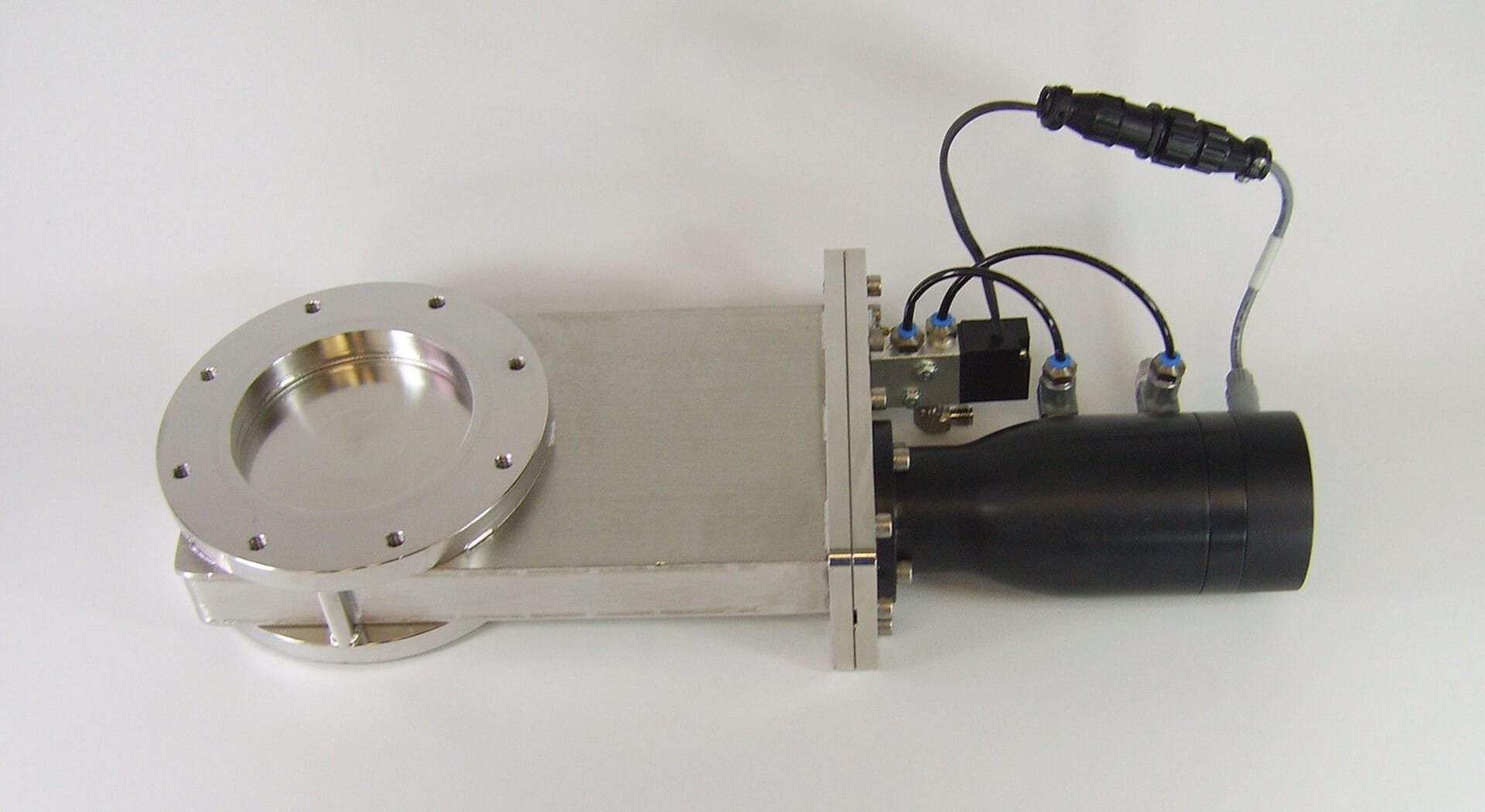

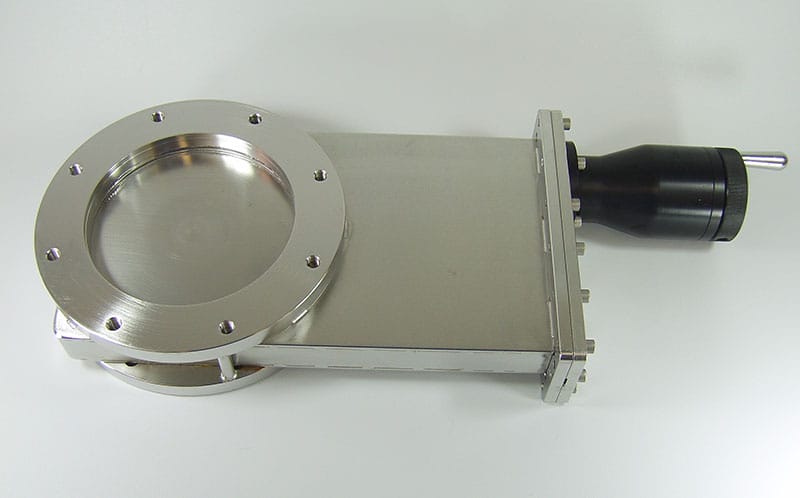

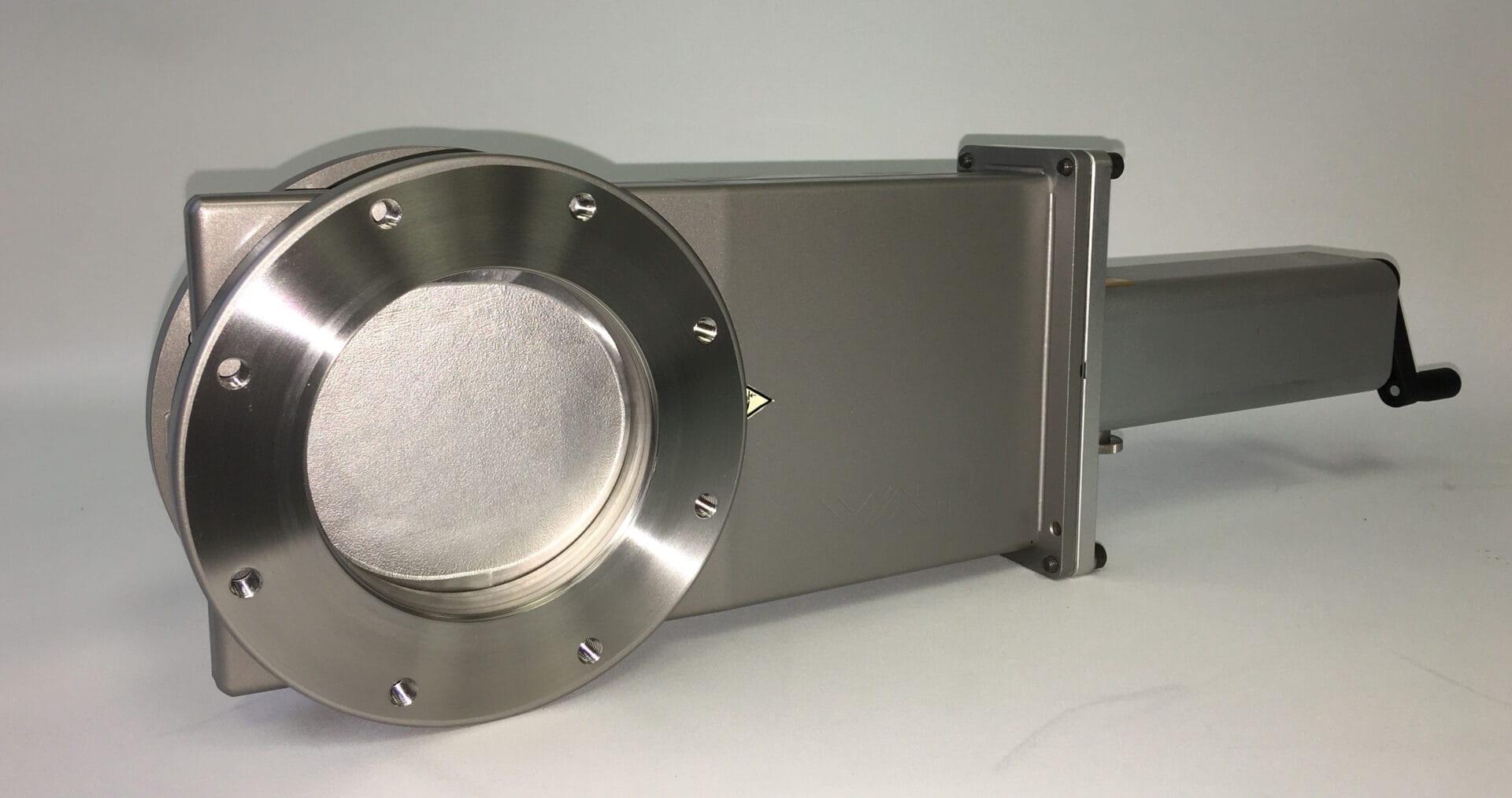

- 853-012200-002 Lam Research Gate Drive Inner Assembly

- 853-012200-004 Lam Research 9600 Gate Drive Inner Assembly

- 853-012261-001 Lam Research Gate Drive Inner Assembly

- 853-012875-002 Lam Research 9600 Gate Drive Inner Assembly

- 853-012875-001 Lam Research Gate Drive Inner Assembly

- 853-012100-003 Lam Research Arm Housing Assembly

- 853-012100-001 Lam Research Arm Housing Assembly

- 853-012100-004 Lam Research Arm Housing Assembly

- 853-442064-002 LAM Research Gate Drive Inner Assembly

- 853-442078-001 Lam Research Gate Drive Inner Assembly

- C-2134-086-0001 Ebara Rotary Union

- 852-011060-001 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive)

- 853-012123-500 Lam Research Harmonic Drive

- 0010-25303 | Applied Materials 300MM LK Pad Conditioner Arm

- 0010-12313 | Applied Materials 300MM HVM Reflexion Pad Conditioner Arm

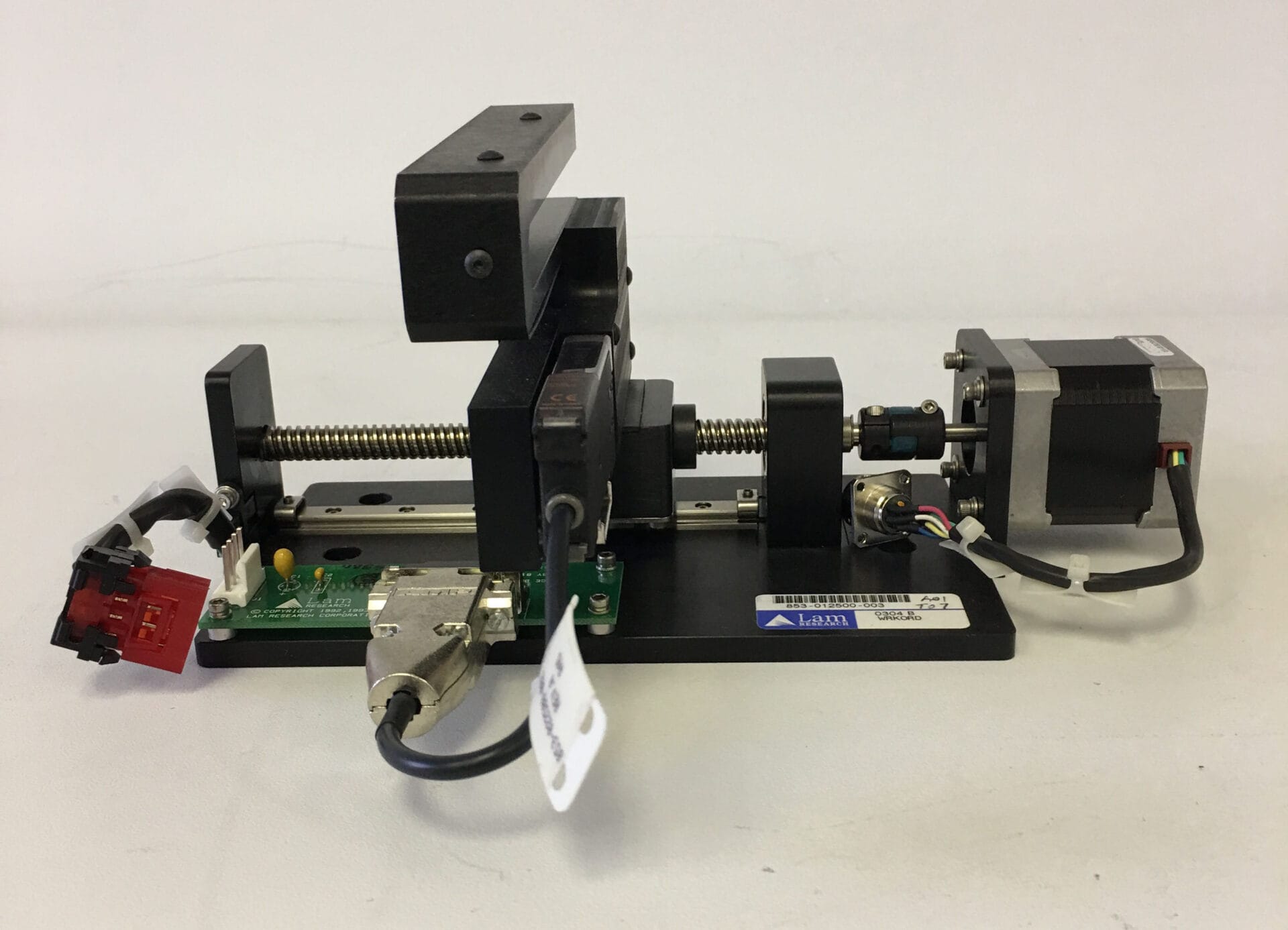

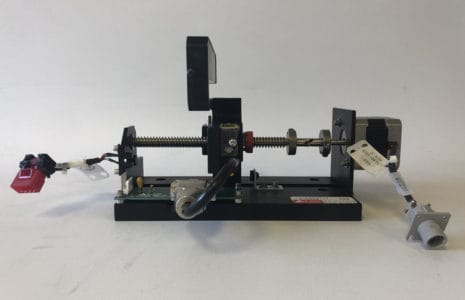

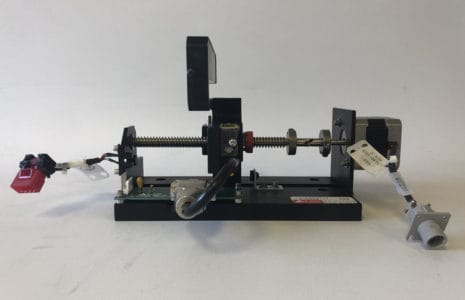

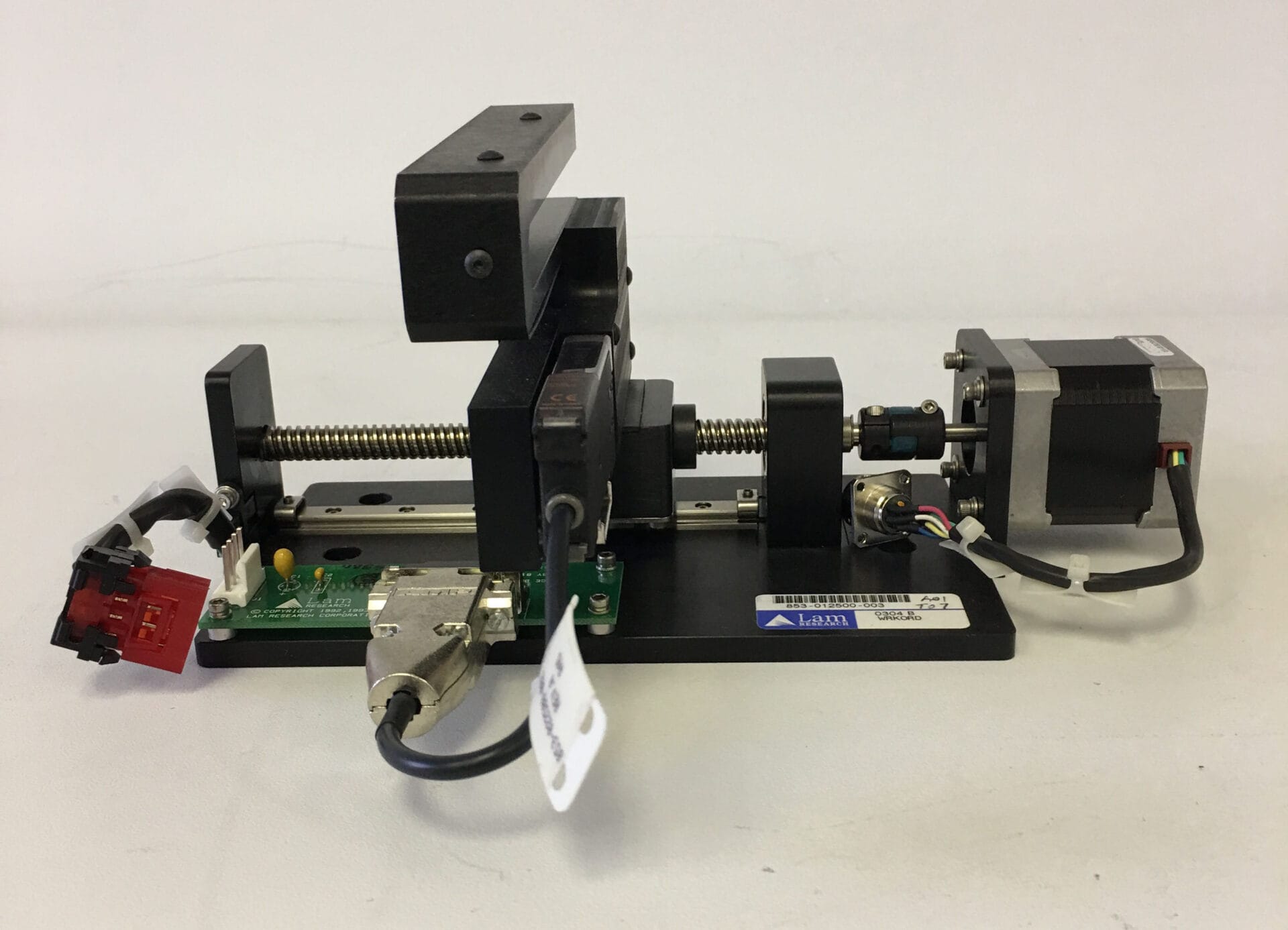

- 853-012500-003 | Edge Sensor Assembly

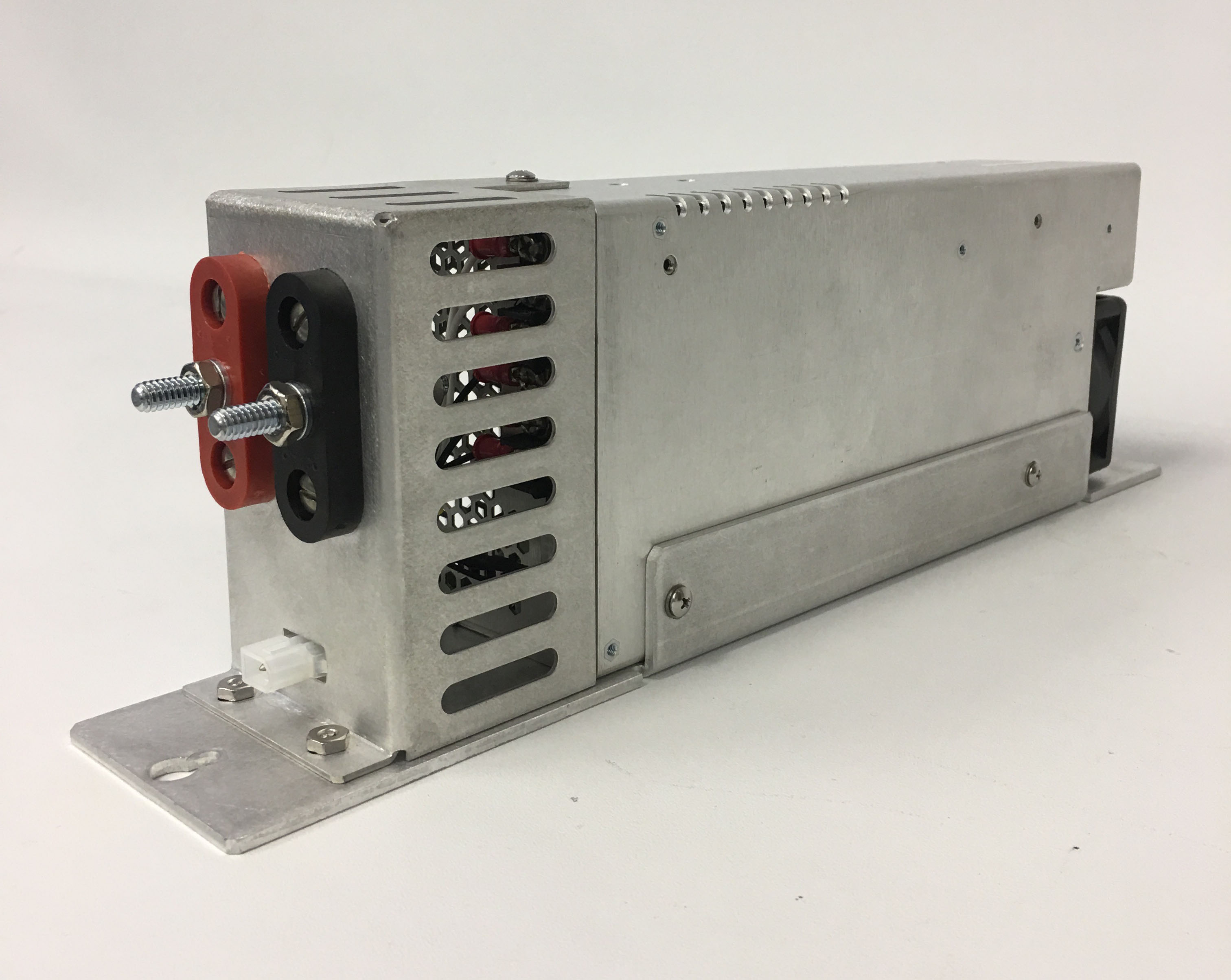

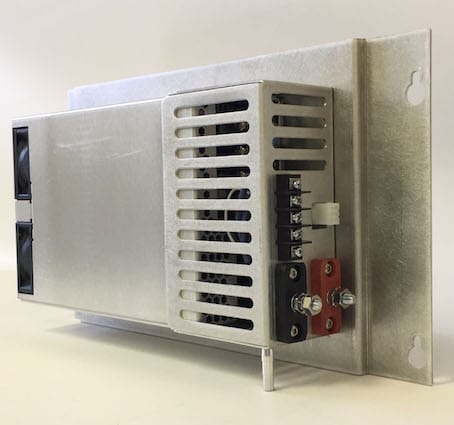

- SG660-091821-001 | Semigroup Engineered **New** Drop in Replacement for Lam Power Supply 660-091821-001, +5, +15, -15

- SG660-091820-001 | Semigroup** New** Drop in replacement (Engineered by Semigroup) for Lam Research Power Supply 660-091820-001

- 853-012500-002| Edge Sensor Assembly

- INR-244-215A | SMC Chiller

- INR-244-117A | SMC Chiller

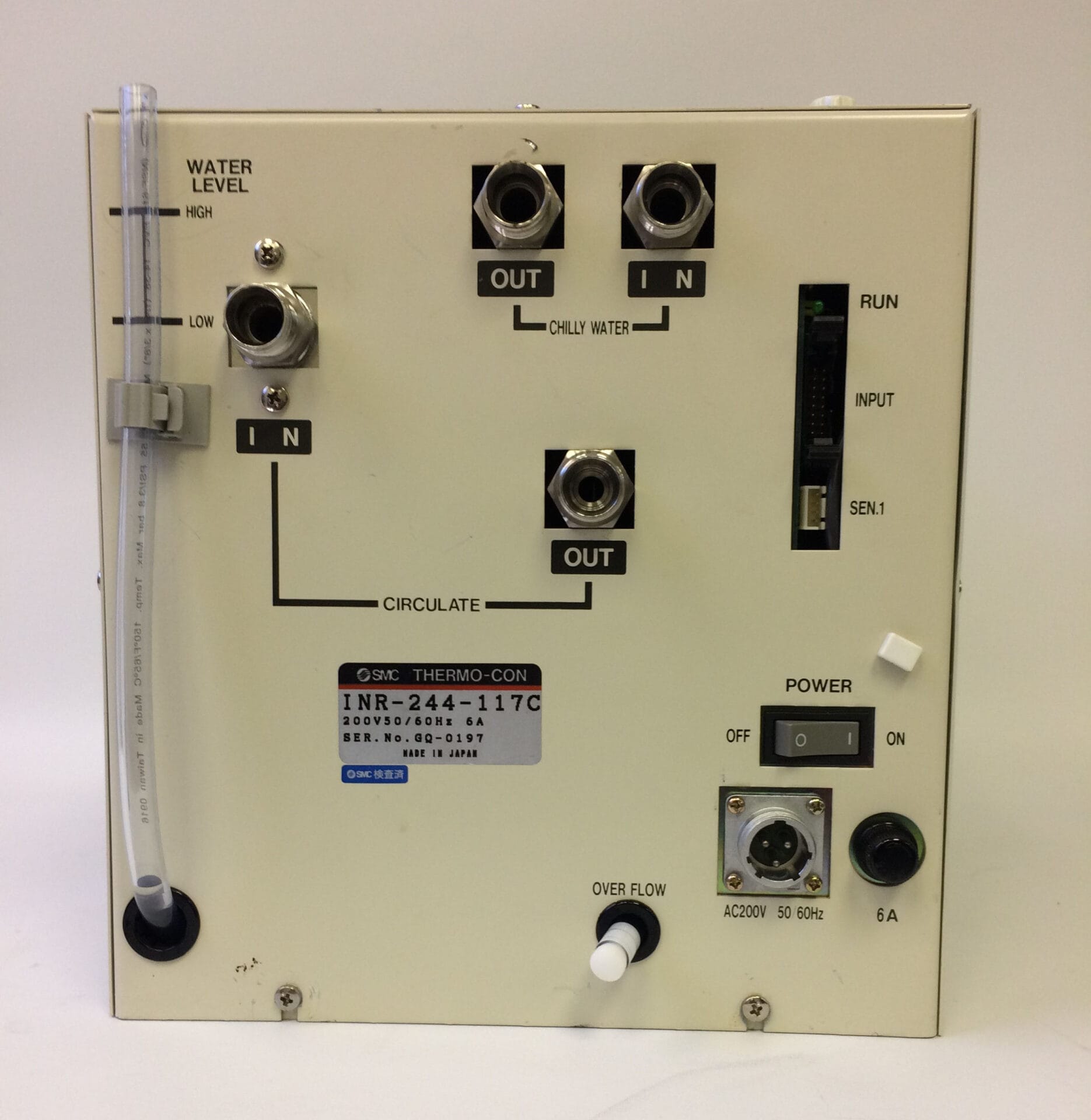

- INR-244-117C | SMC Chiller

- INR-244-112 | SMC Chiller

- INR-244-117B | SMC Chiller

- INR-244-602A | SMC Chiller

- 242-027-0142 | Electrocraft E242 Servo Motor

- 0190-14344W-R | NSK Motor & Controller Set Service

- 0190-14344-R | NSK Motor & Controller Set Service

- R88M-U75030VA-S1 | OMRON AC Servo Motor

- HC-MF23G1-UE | Mitsubishi AC Servo Motor

- HC-MF43BD-UE | Mitsubishi AC Servo Motor

- 830003428 | Maxon Servo Motor

- P50B07040DCS00 | Sanyo Denki AC Servo Motor BL Super P5

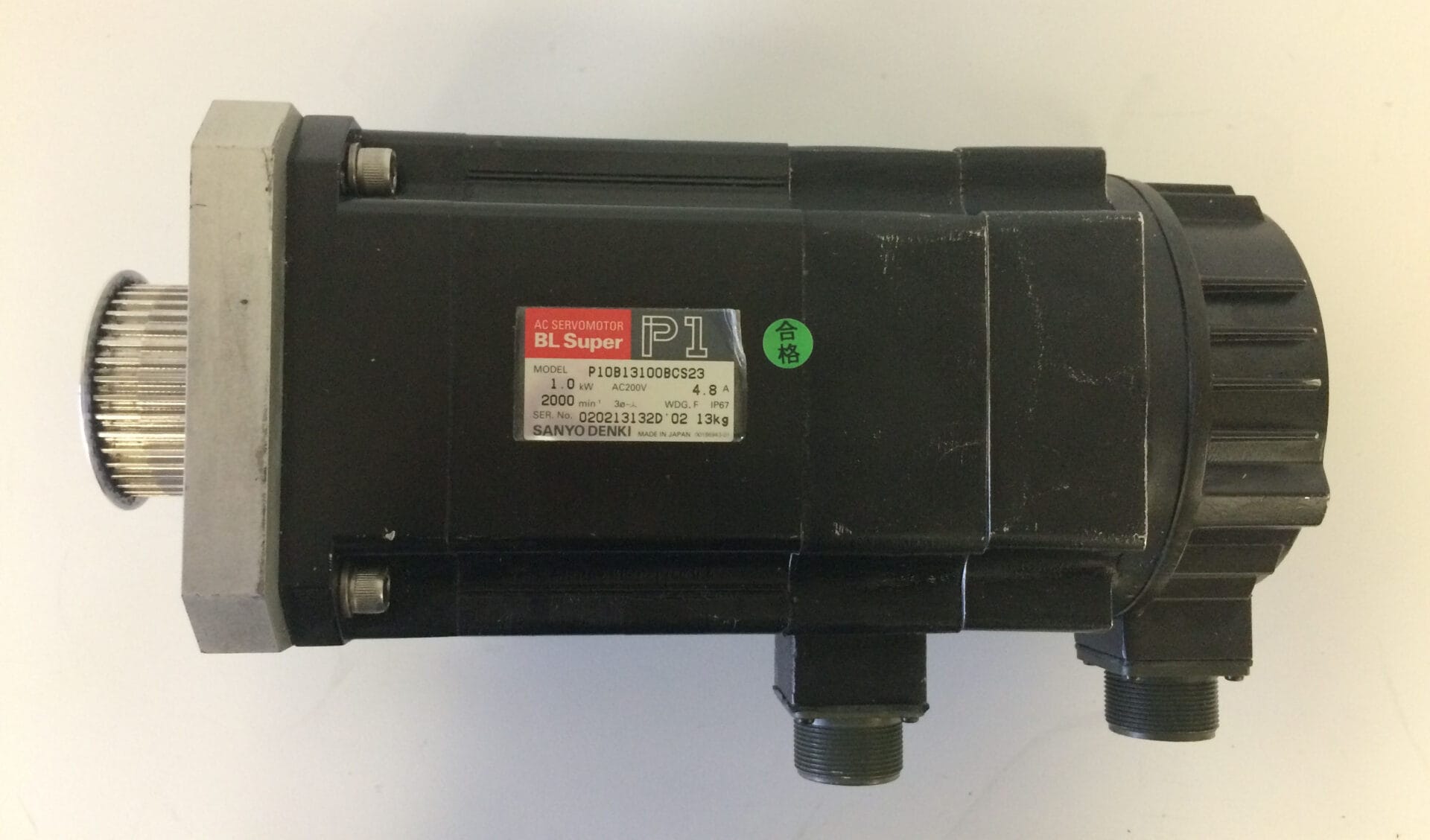

- P10B13100BCS23 | Sanyo Denki AC Servo Motor

- P50B03003DXS00 | Sanyo Denki AC Servo Motor

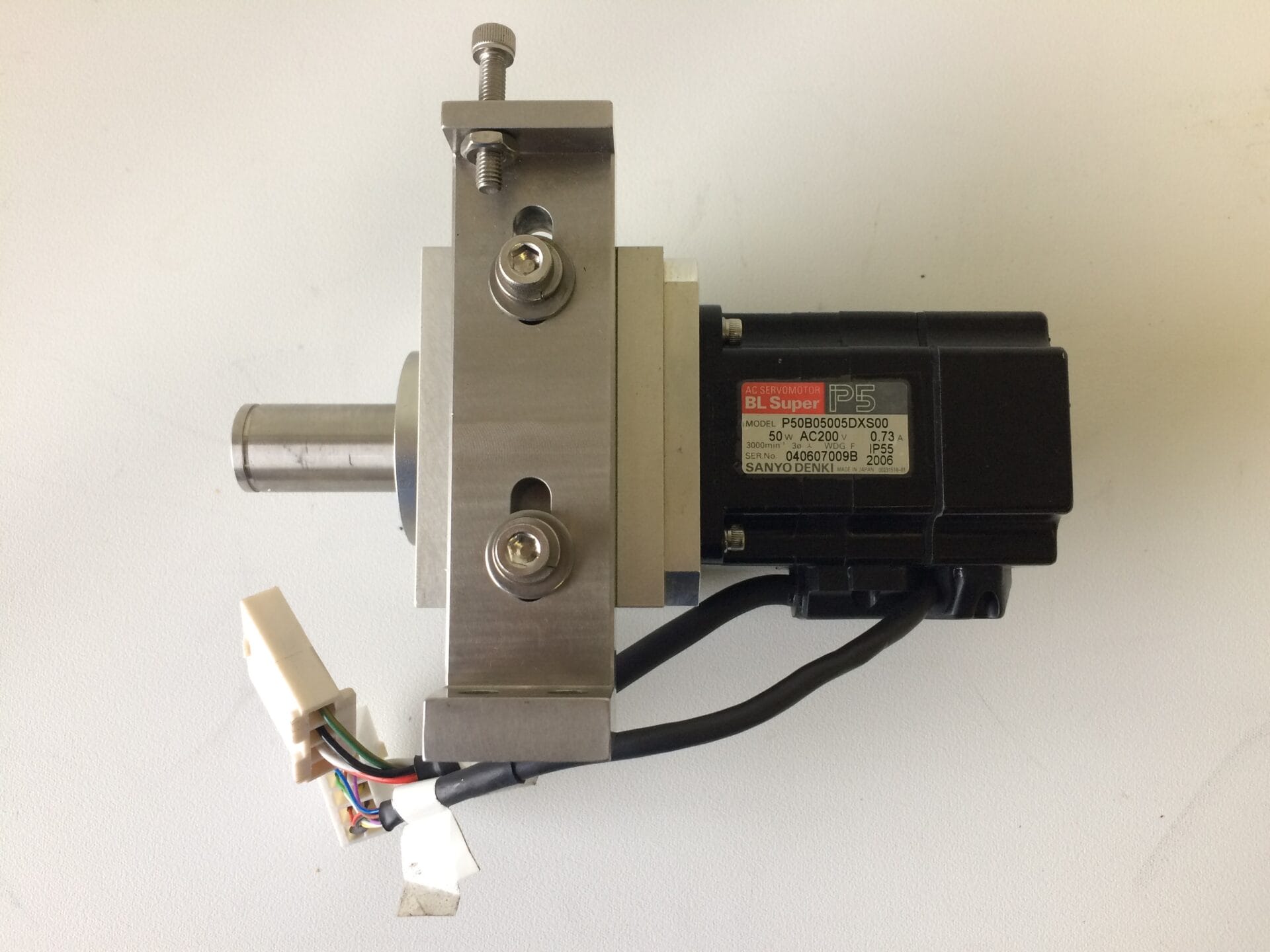

- P50B05005DXS00 | Sanyo Denki AC Servo Motor

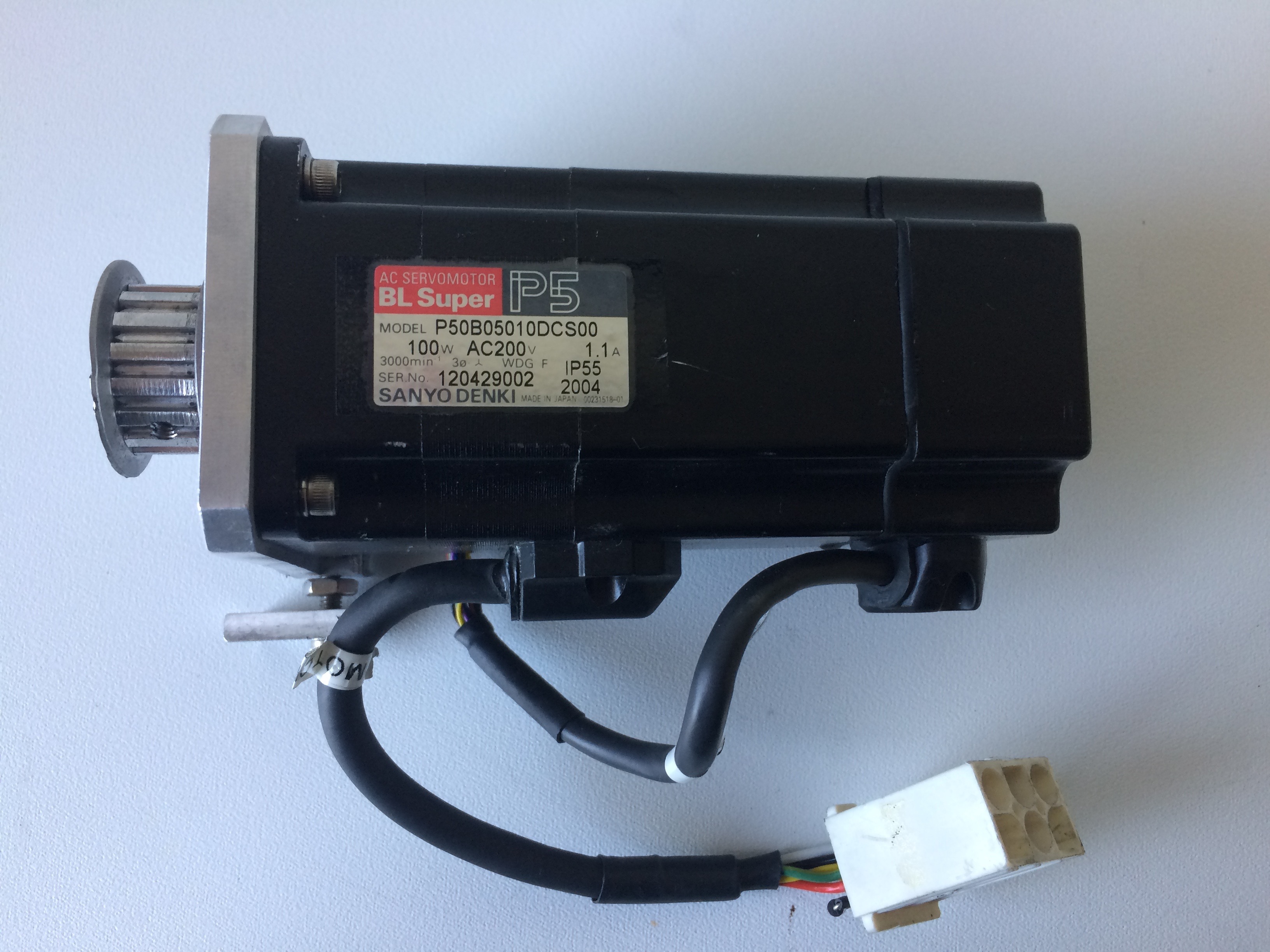

- P50B05010DCS00 | Sanyo Denki AC Servo Motor

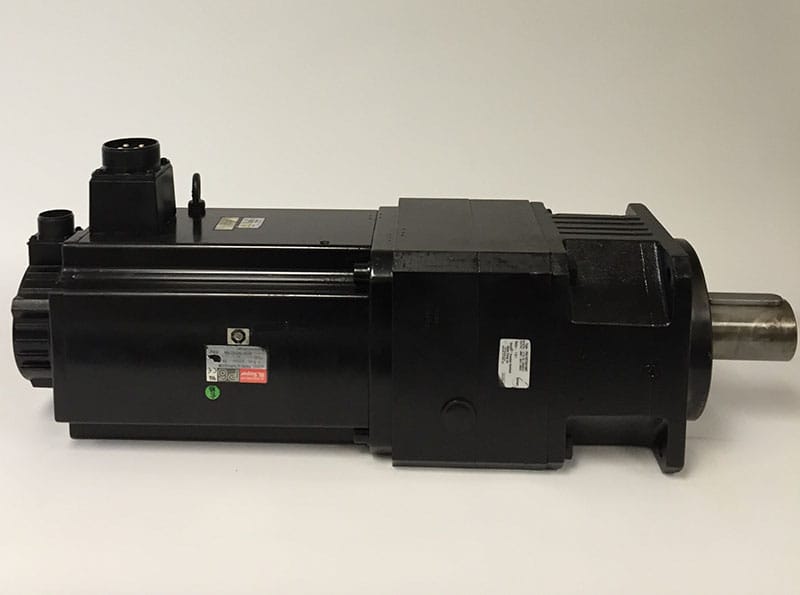

- SGMS-20A6AB | Yaskawa AC Servo Motor

- HC-MF23BG1D-UE | Mitsubishi AC Servo Motor

- R02SAKOE UTOPI-200SE | Yaskawa Minertia DC Servo Motor

- SGMAH-01AAAP18 | Yaskawa AC Servo Motor

- SGMAH-01AAF41 | Yaskawa AC Servo Motor

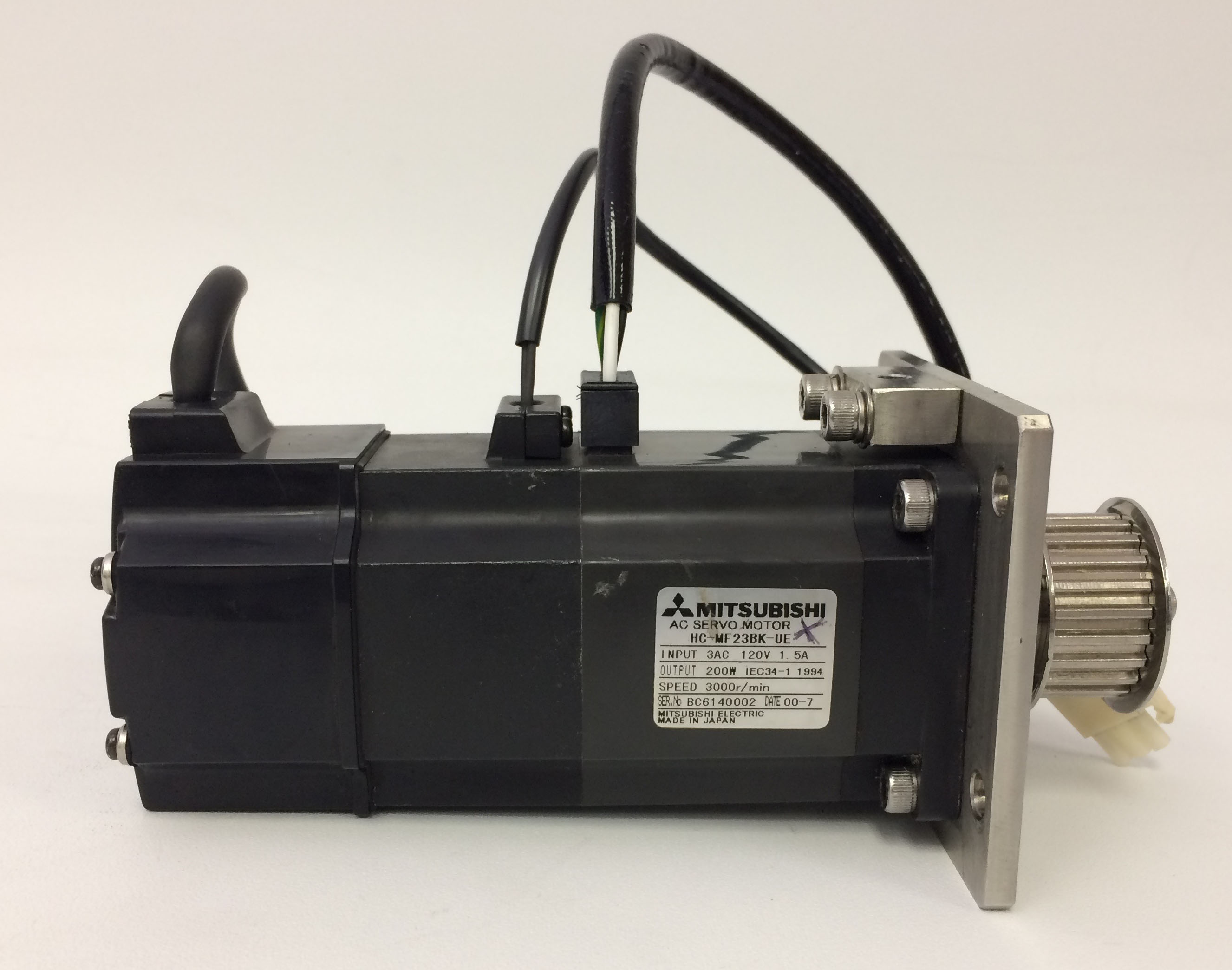

- HC-MF23BK-UE | Mitsubishi AC Servo Motor

- SGMS-50A6AB | Yaskawa AC Servo Motor

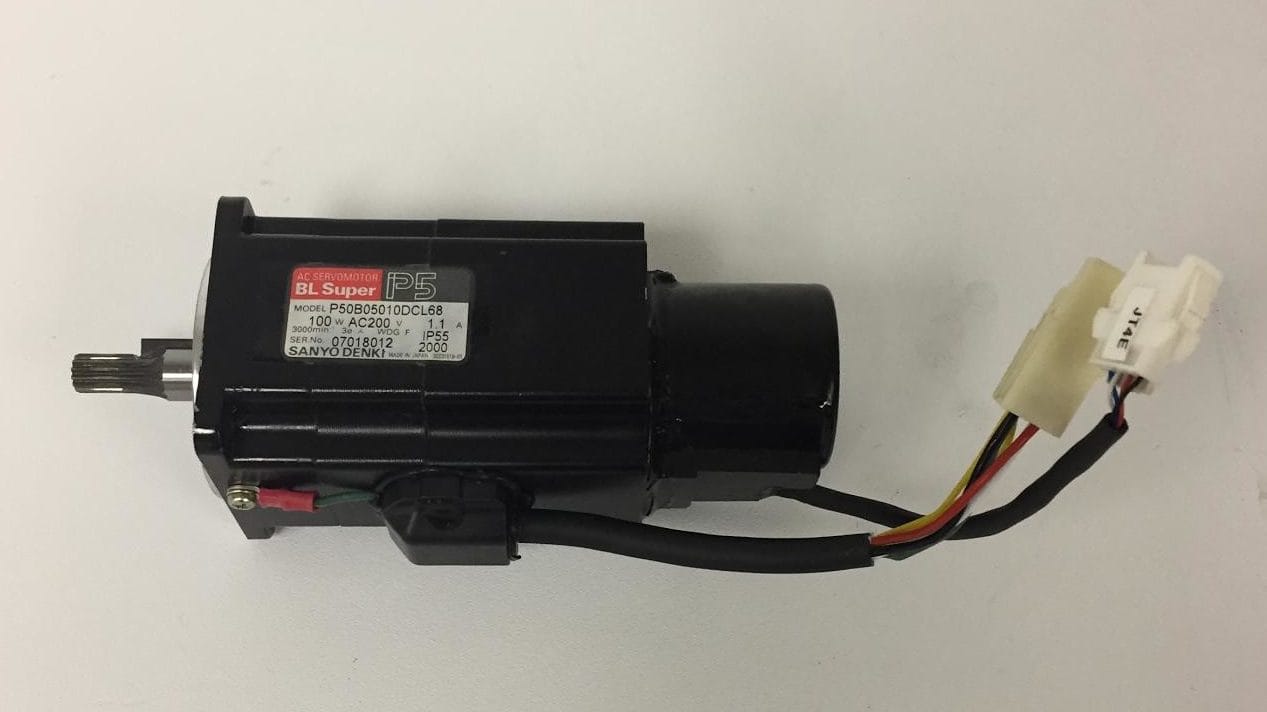

- P50B05010DCL68 | Sanyo Denki Servo Motor

- SGMPH-04AAE41D | Yaskawa Servo Motor

- SGMP-02U314M | Yaskawa Servo Motor

- SGM-02A3YB11 | Yaskawa Servo Motor

- SGM-02U3B4L | Yaskawa Servo Motor

- P60B18750RXS00M | Sanyo Denki Servo Motor

- SGMP-01U314M | Yaskawa Servo Motor

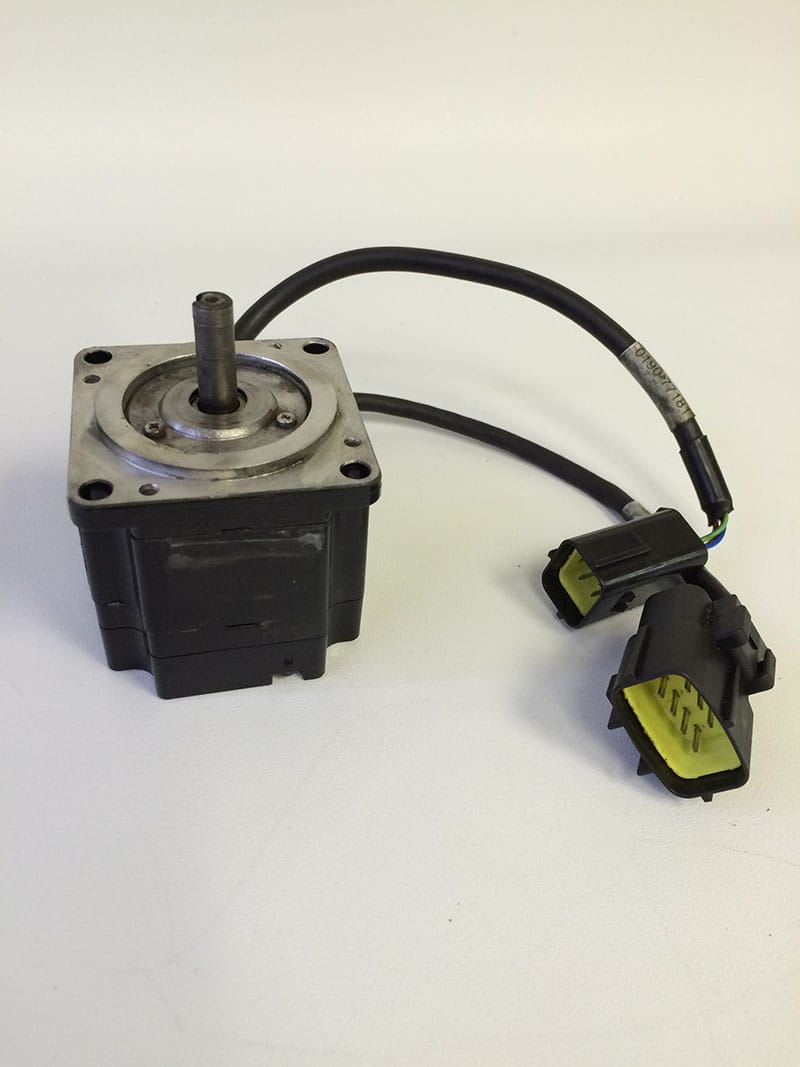

- 1080-00036 | NSK Motor Service

- RZ0810FN507 | NSK Motor Service

- EP0810AF5-05 | NSK Controller

- EP0810AF8-05 | NSK Controller

- DR303AE9MA| Ametek Rotron Regenerative Blower

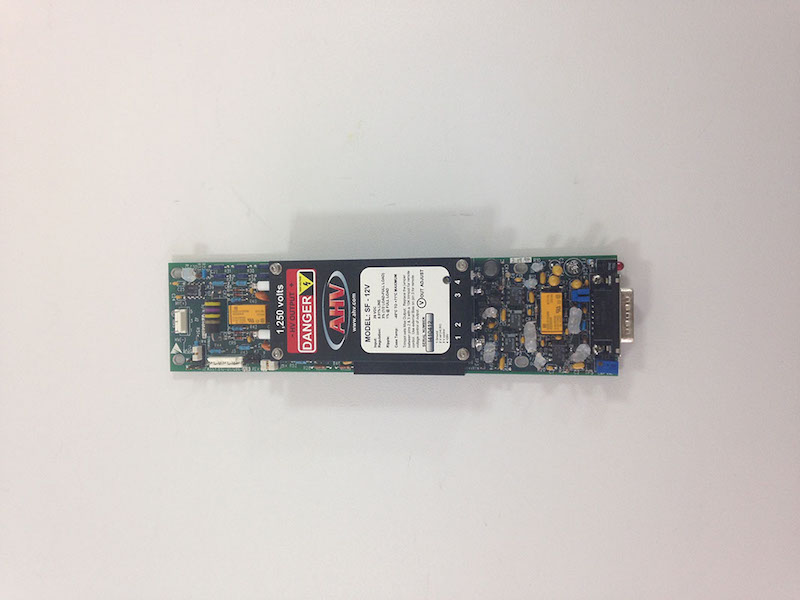

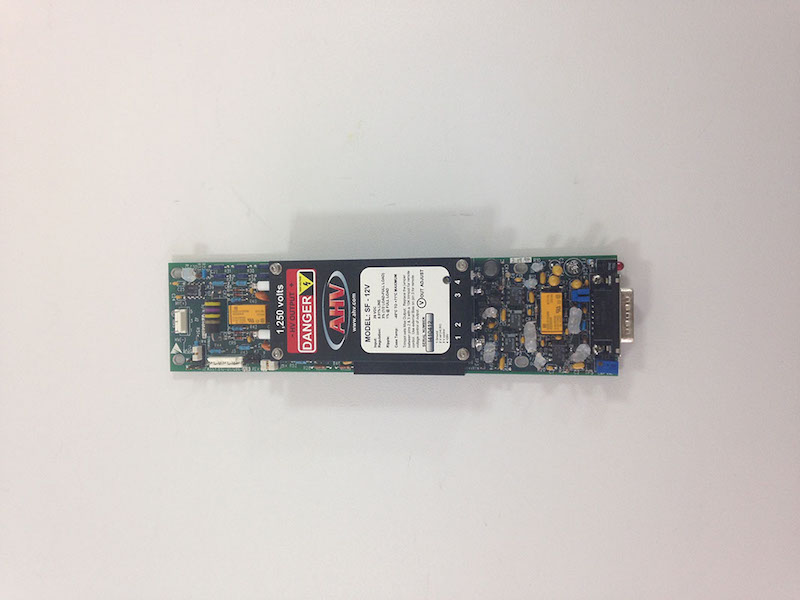

- 810-017086-018 | ESC Power Supply

- 810-017086-007 | ESC Power Supply

- 810-017086-008 | ESC Power Supply

- 810-017086-010 | ESC Power Supply

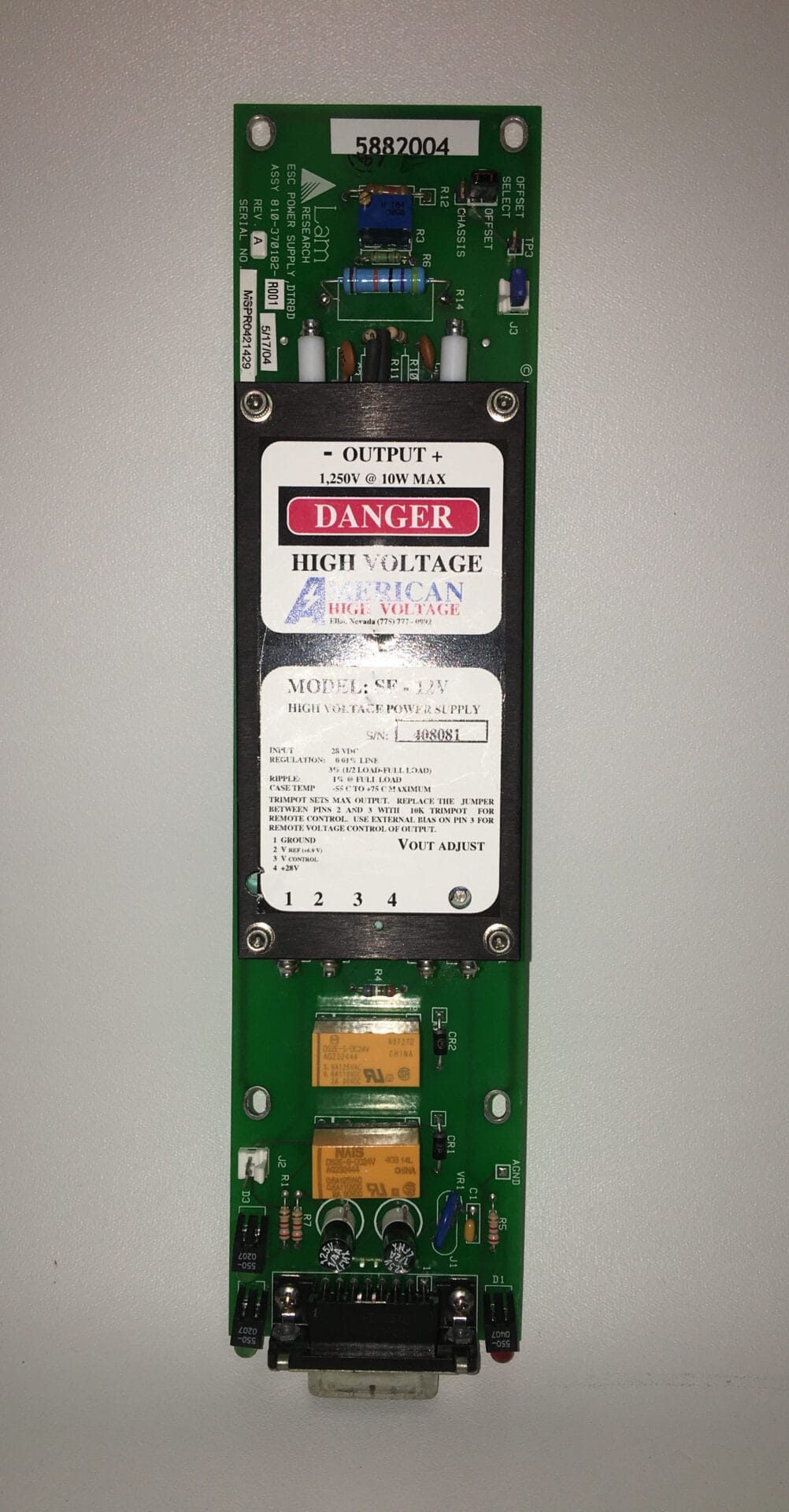

- 810-370182-001 | Lam Research Assembly, PCB, ESC Power Supply, DTRBD

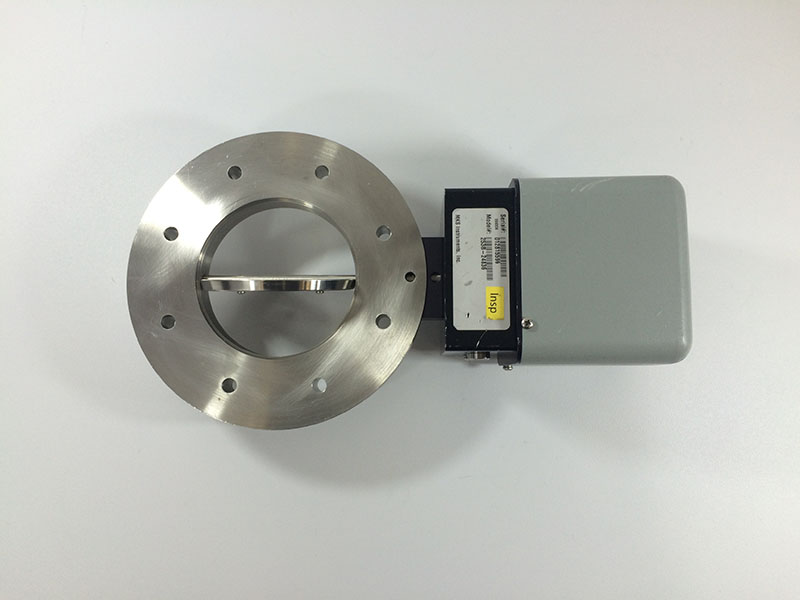

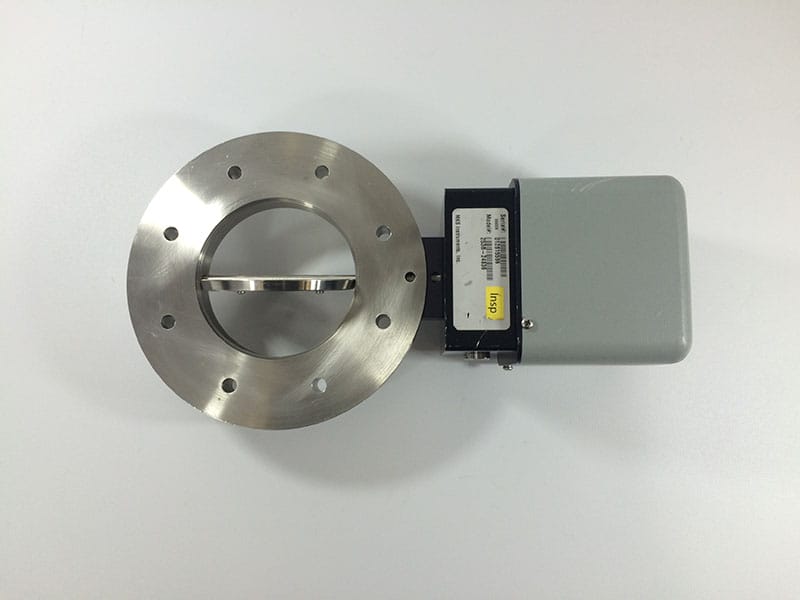

- 683-24562 | MKS Throttle Valve

- 253B-24836 | MKS Throttle Valve

- 153D-15006 | MKS Throttle Valve

- 253B-1-40-1 | MKS Throttle Valve

- 153D-2-50-2 | MKS Throttle Valve

- 153D-12018 | MKS Throttle Valve

- 283152 | MKS Throttle Valve

- B65351000 | GVI 100P Edwards Isolation Valve

- B65401000 | GVI 160M Edwards Isolation Valve

- B65301000 | GVI 100M Edwards Isolation Valve

- 09140-PE01 | VAT Gate Valve Manual

- 02-177392-00 | Novellus Platen Rebuild

- 0750-700176 | Novellus 676 Main Cylinder Assembly

- 0750-111515 | Novellus Momentum Main Cylinder Assembly

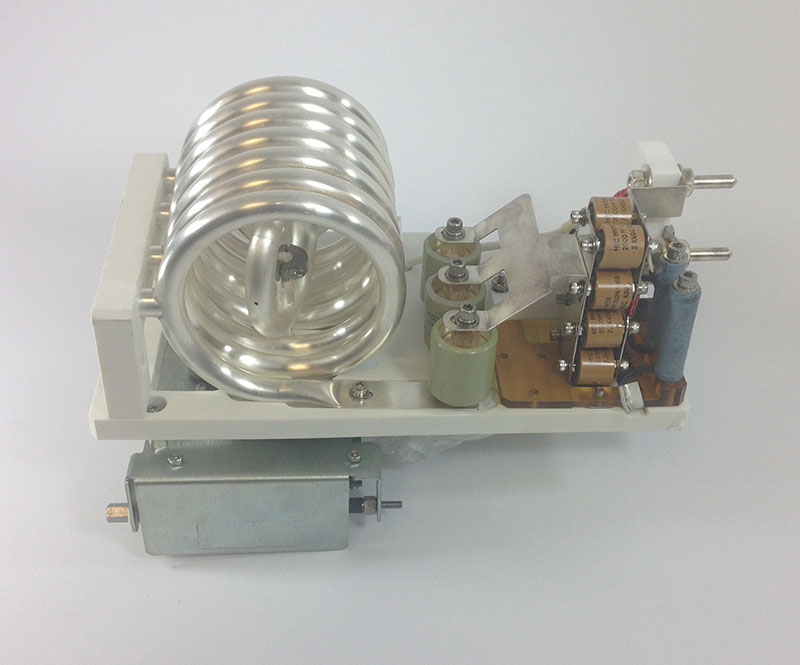

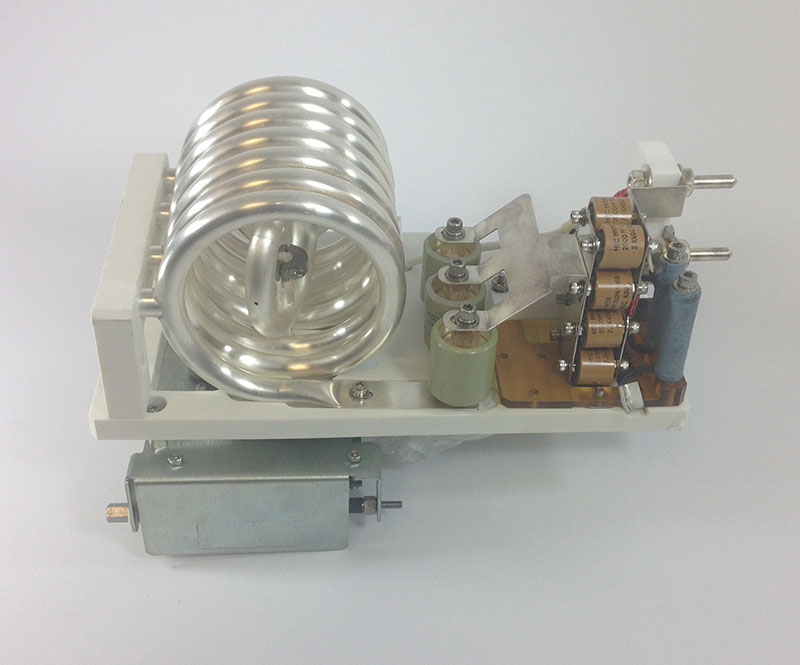

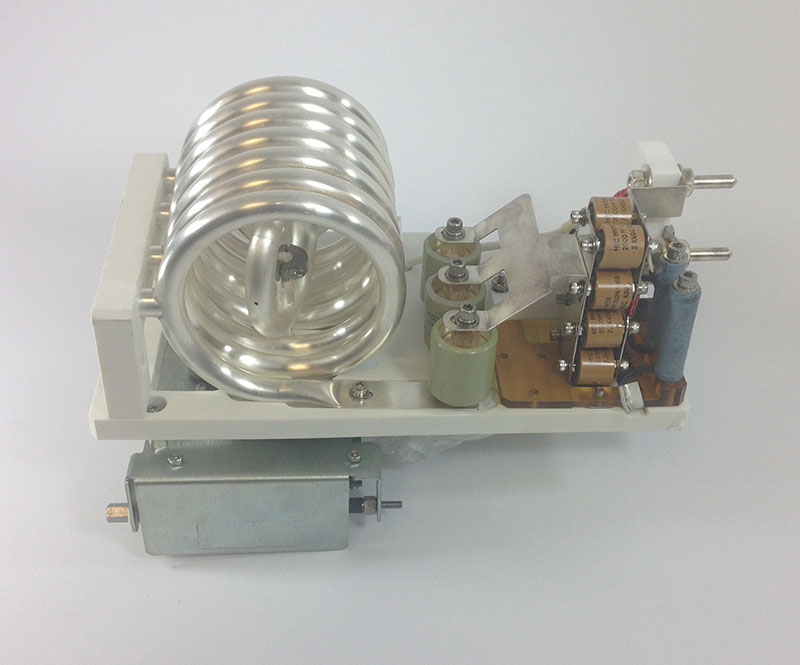

- 853-250001-121 | LAM Research RF Mini-Match

- 853-250001-024 | LAM Research RF Mini-Match

- 853-250001-023 | Lam Research RF Mini-Match (ASSY, RF MATCH, ESC PK D)

- 853-250001-021 | LAM Research RF Mini-Match

- 853-330951-001 | LAM Research RF Mini-Match

- 853-015130-503| LAM Research RF Mini-Match

- 853-330951-021 | LAM Research RF Mini-Match

- 853-025083-022 | LAM Research RF Mini-Match

- 853-025083-003 | LAM Research RF Mini-Match

- 853-025083-004 | LAM Research RF Mini-Match

- 853-025083-002 | LAM Research RF Mini-Match

- 853-025083-001 | LAM Research RF Mini-Match

- 853-015130-205| LAM Research RF Mini-Match

- 853-015130-204 | LAM Research RF Mini-Match

- 853-015130-202 | LAM Research RF Mini-Match

- 853-015130-103 | LAM Research RF Mini-Match

- 853-015130-102 | LAM Research RF Mini-Match

- 853-015130-006 | LAM Research RF Mini-Match

- 853-015130-003 | LAM Research RF Mini-Match

- 853-015130-004 | LAM Research RF Mini-Match

- 853-015130-002 | LAM Research RF Mini-Match

- SGM-04UWB4L | Yaskawa AC Servo Motor

- SGM-01U3AP01 | Yaskawa AC Servo Motor

- GENMARKS GB4 Series Repair

- 20705 | MKS Thin Film Novellus CVD 300mm IREPD Refurbishment

- 300MM AMAT LK Spindle Refurbishment

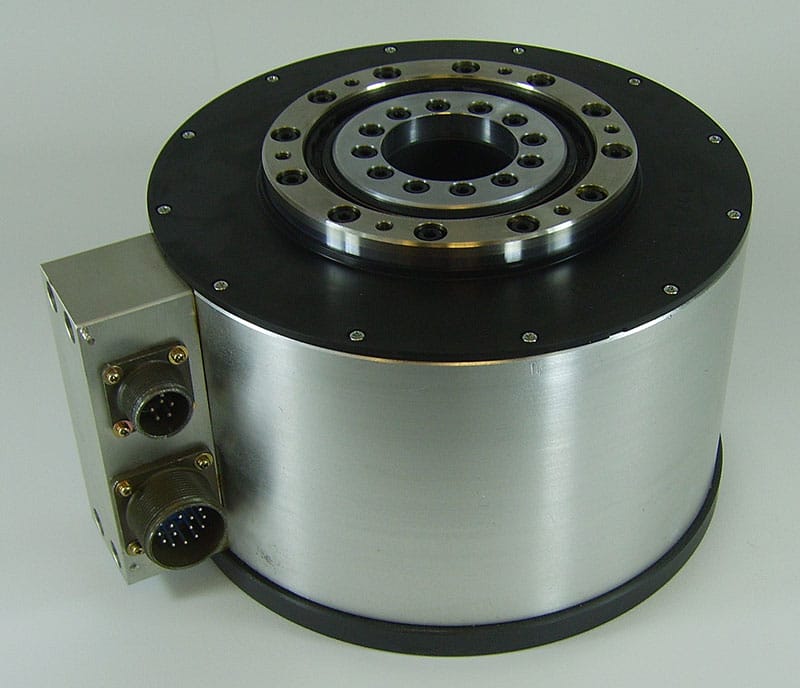

- ROTARY UNION ASSEMBLY OVERHAUL PROGRAM

- 853-012123-001 Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-032776-002 Lam Research Paddle Lifter - Quick Exchange Option and Repair

- 853-032776-001 Lam Research Paddle Lifter - Quick Exchange Option and Repair

- 853-012200-002 Lam Research Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-021924-003 Lam Research Paddle Lifter - Quick Exchange Option and Repair

- 853-032776-605 Lam Research Paddle Lifter - Quick Exchange Option and Repair

- 853-012175-004 Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-012175-003 Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-012175-002 Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-012175-001 Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-012123-004 | Lam Research Harmonic Drive - Quick Exchange Option and Repair

- 853-001198-001 AutoEtch Outer Gate Assembly - Quick Exchange Option and Repair

- 853-001198-002 AutoEtch Inner Gate Assembly - Quick Exchange Option and Repair

- SG660-007612-001 | Semigroup** New** Drop in replacement (Engineered by Semigroup) for Lam Research Power Supply 660-007612-001, 24 Volt DC 40 Amp

- 09140-PE01-BO | VAT Gate Valve Manual

- SG-DR303AE9MA| Semigroup Drop in Replacement for Ametek Rotron Regenerative Blower

- 853-012500-002| Edge Sensor Assembly - Quick Exchange Option and Repair

- 853-012500-003 | Edge Sensor Assembly - Quick Exchange Option and Repair

- INR-244-117A | SMC Chiller - Quick Exchange Option and Repair

- 852-011060-001 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive) - Quick Exchange Option and Repair

- 853-012100-003 Lam Research Arm Housing Assembly - Quick Exchange Option and Repair

- 853-012100-004 Lam Research Arm Housing Assembly - Quick Exchange Option and Repair

- 853-012100-001 Lam Research Arm Housing Assembly - Quick Exchange Option and Repair

- 853-442078-001 Lam Research Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-442064-002 LAM Research Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-012200-004 Lam Research 9600 Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-012261-001 Lam Research Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-012875-001 Lam Research Gate Drive Inner Assembly - Quick Exchange Option and Repair

- 853-012875-002 Lam Research 9600 Gate Drive Inner Assembly - Quick Exchange Option and Repair

- STP-A2203 | Boc Edwards Seiko Seiki Turbo Pump

- STP-A803 | Boc Edwards Seiko Seiki Turbo Pump

- STP-603 | Boc Edwards Seiko Seiki Turbo Pump

- Mass Flow Controllers and Liquid Flow Meters

- 853-032190-008 | LAM TCP Upper Match

- 853-032190-008 | LAM TCP Upper Match - Quick Exchange Option and Repair

- 853-800089-103 | BIAS Match

- 249021 | Fusion Gemini 3 – Axis Robot Assembly

- 322703 | Eaton Gemini 3 – Axis Robot Assembly

- 322703-Z | Axcelis Gemini 3 – Axis Robot Assembly

- SG853-021917-108 | 200mm Isotropic Heated Paddle for LAM 853-021917-108, ASSY,HTD PADDLE, FDTHR, ISO ETCH

- SG853-021917-008| 200mm Isotropic Heated Paddle LAM 853-021917-008 | ASSY | HTD |PADDLE-FDTHRU | ISO | 8in

- 0190-09116 | AMAT SMC Thermo Con Chiller Refurbishment

- INR-244-808-2 | SMC Thermo-Con Chiller Refurbishment

- EXSH01001UNIV | Varian-Agilent SH-100 Dry Scroll Vacuum Pump Refurbishment

- S716-011564-003 | Lam Research Electrode Upper Graphite SFG - OEM Part 716-011564-003

- 0010-77533 | Applied Materials 200mm MIRRA Titan 1 HEAD

- 853-025903-002 | LAM Low Frequency Autotune

- 853-025903-001 | LAM Low Frequency Autotune – Quick Exchange Option and Repair

- 853-025903-001 | LAM Low Frequency Autotune

- 0190-14344 | NSK Motor & Controller Set Service

- 852-011060-108 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive)

- 852-011060-108 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive) - Quick Exchange Option and Repair

- 852-011060-101 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive)

- 02-307391-00 - Novellus & LAM Research Speed Dome 200mm Refurbishment -

- 02-10387-01 - Novellus / LAM Research 200mm Speed Dome Refurbishment

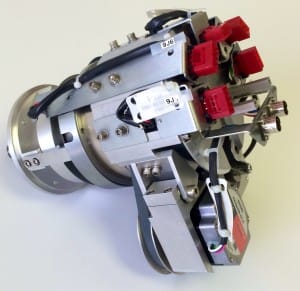

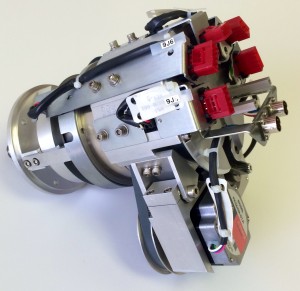

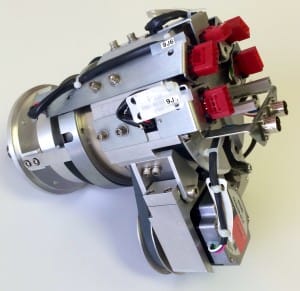

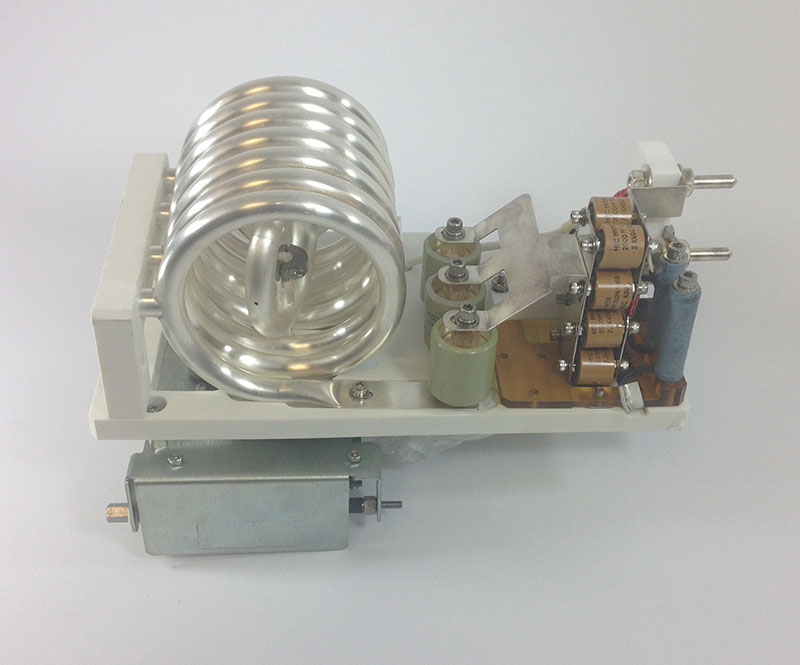

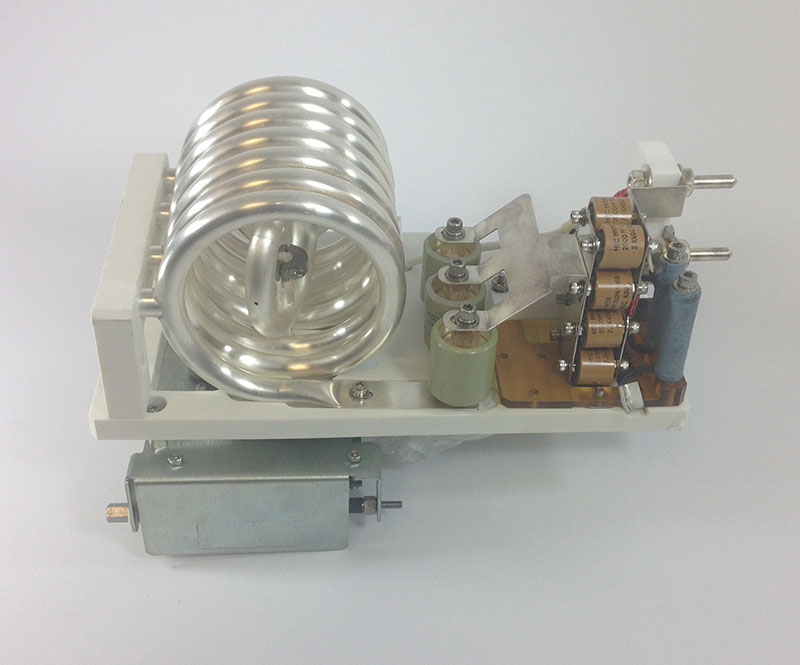

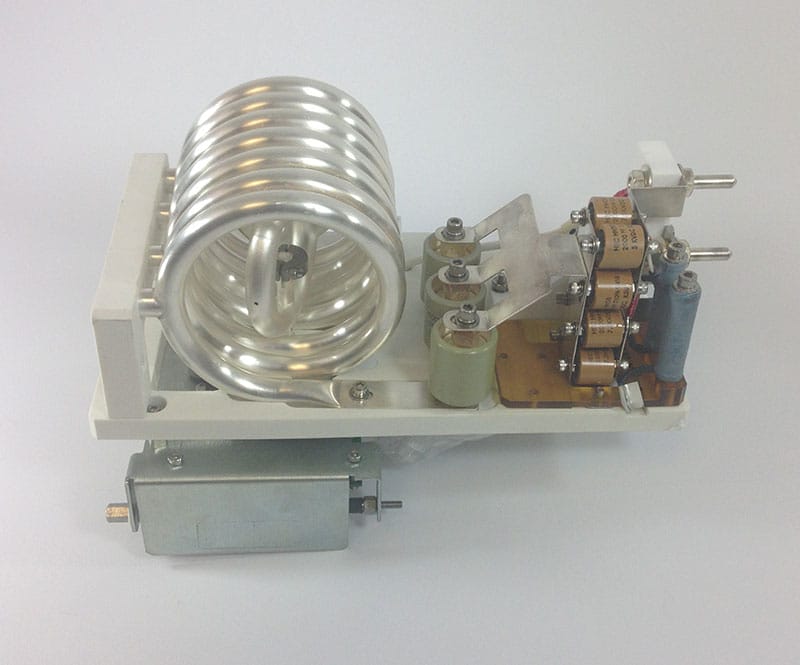

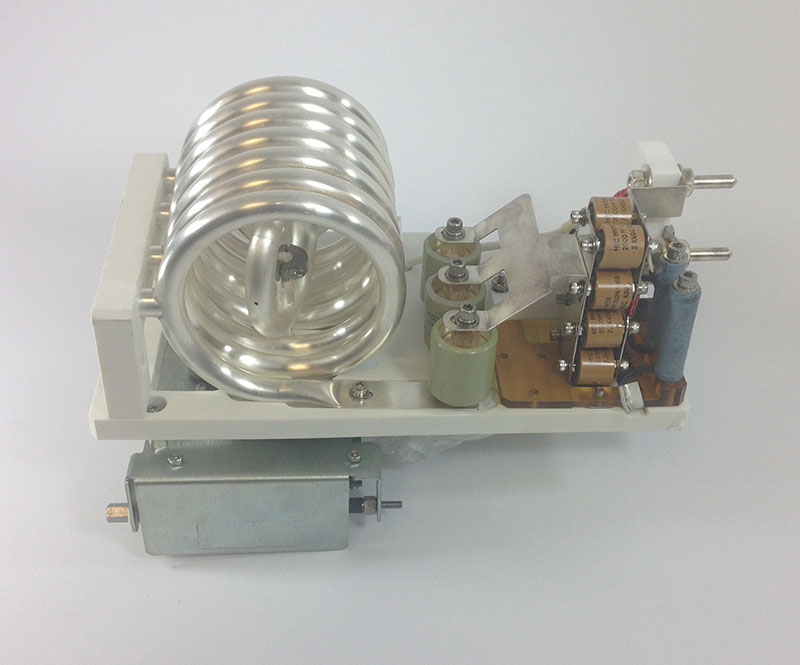

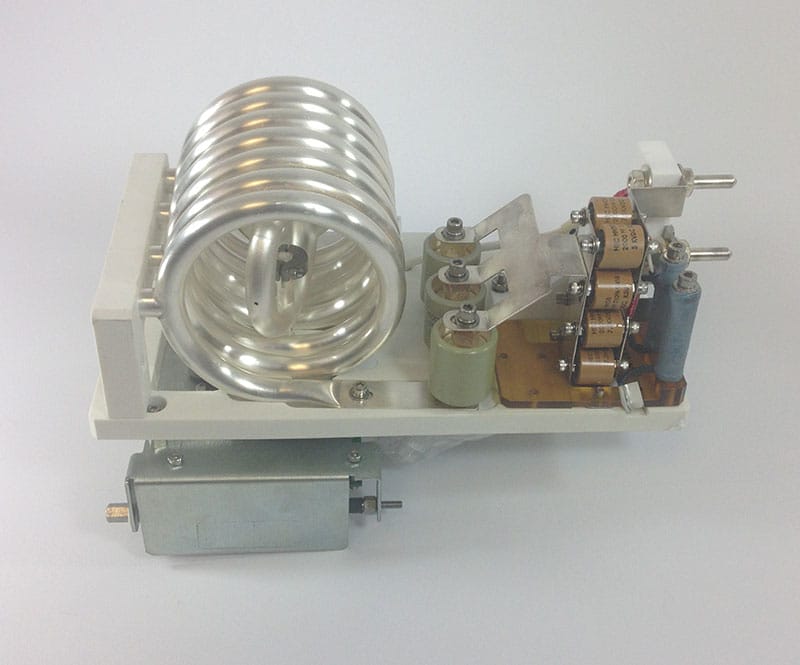

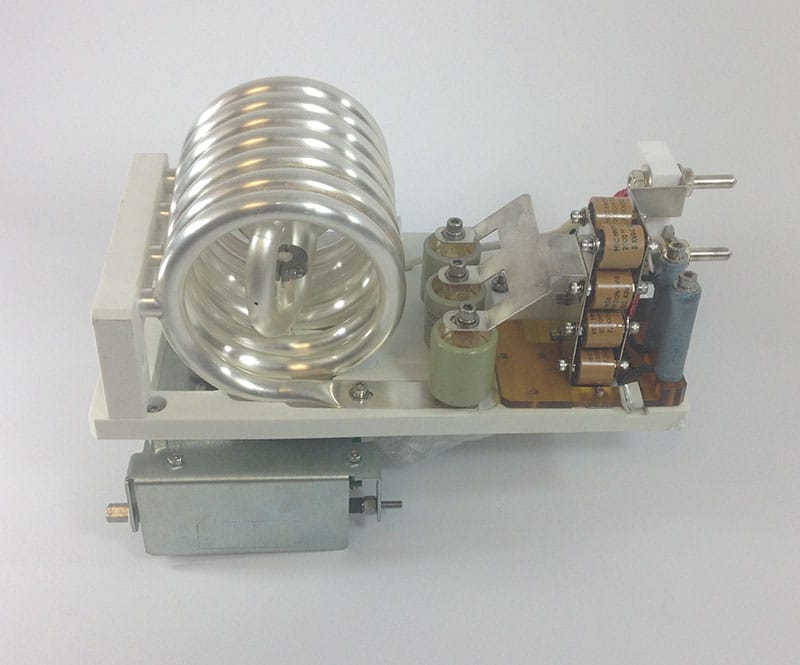

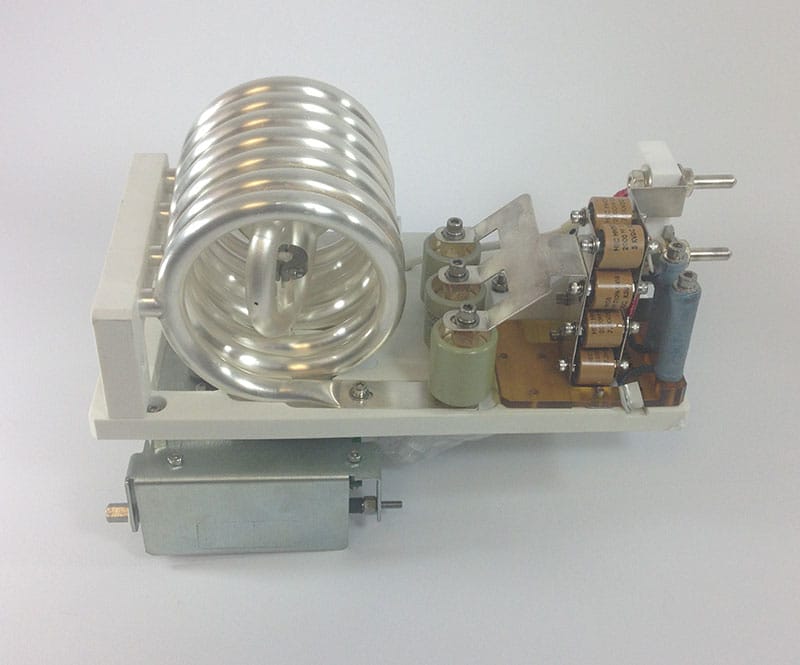

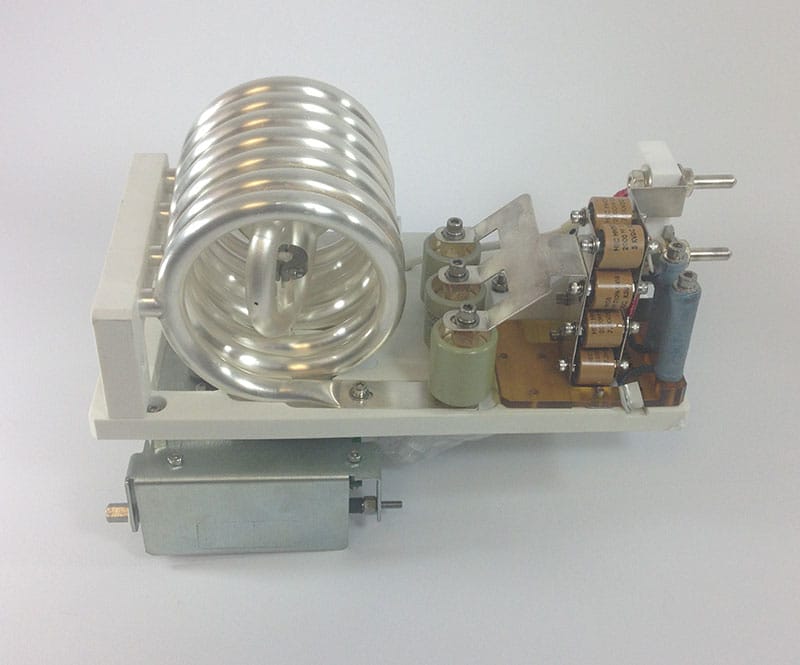

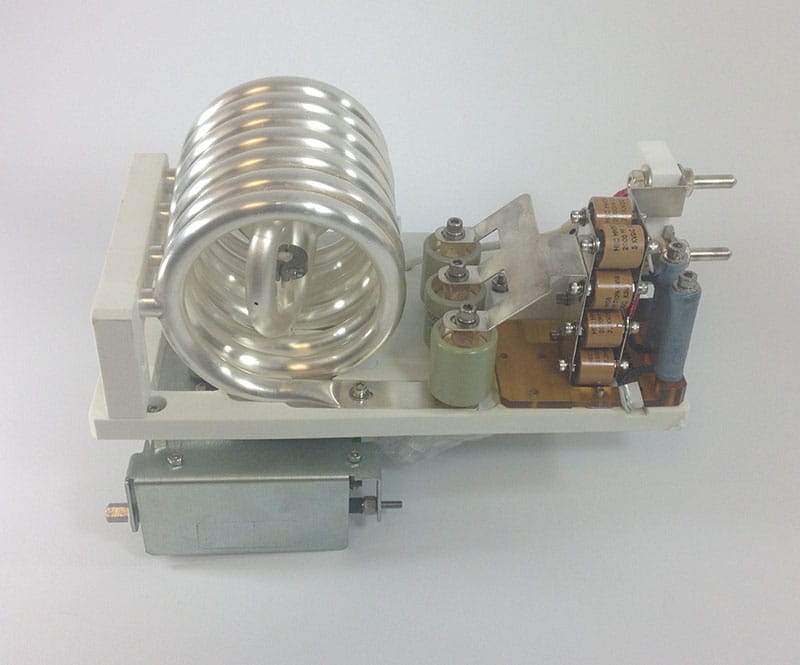

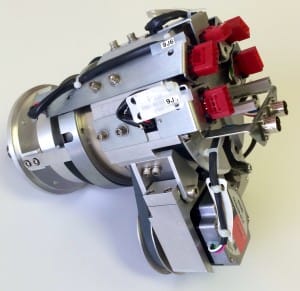

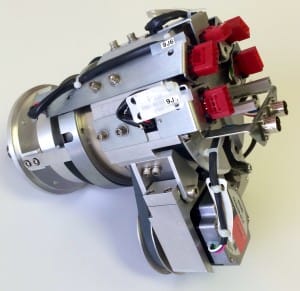

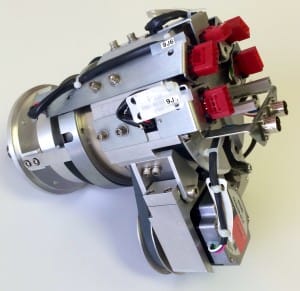

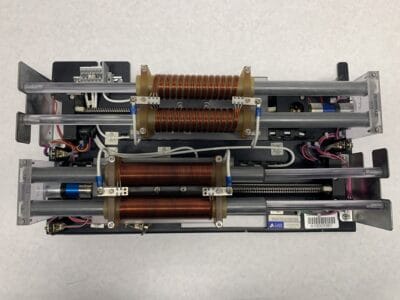

853-012123-001 Lam Research Harmonic Drive

853-012123-001 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

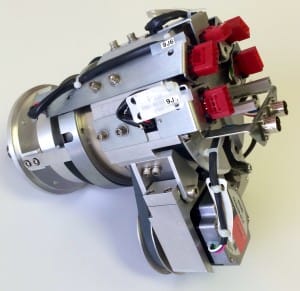

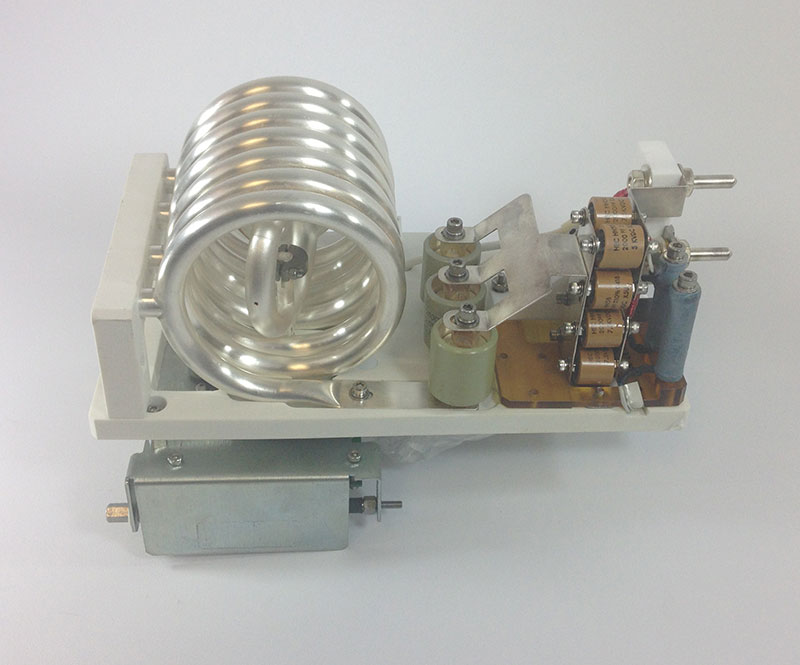

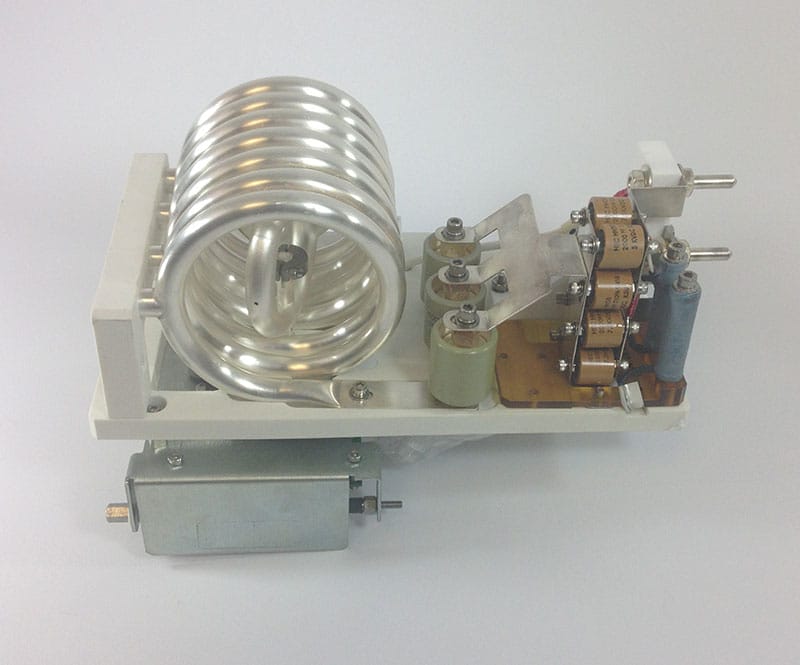

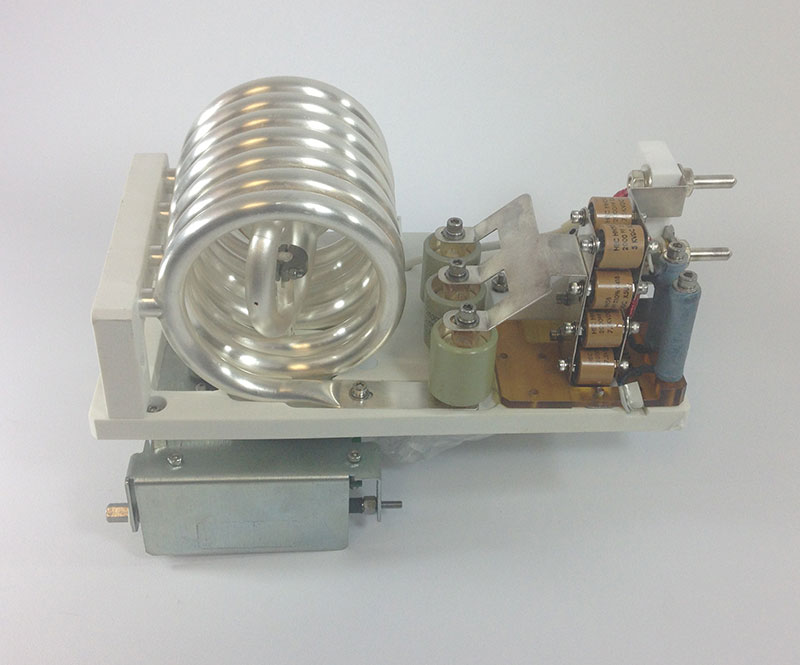

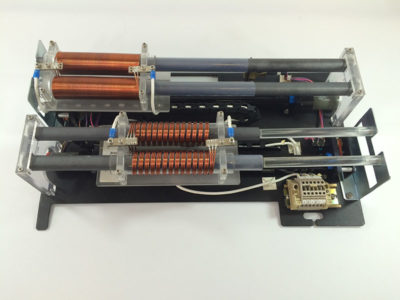

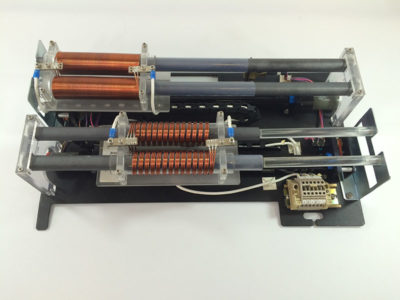

853-012123-004 Lam Research Harmonic Drive

853-012123-004 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Custom Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

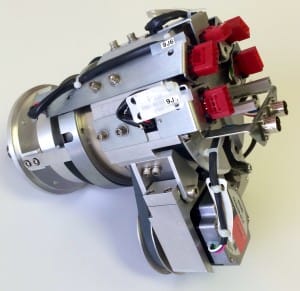

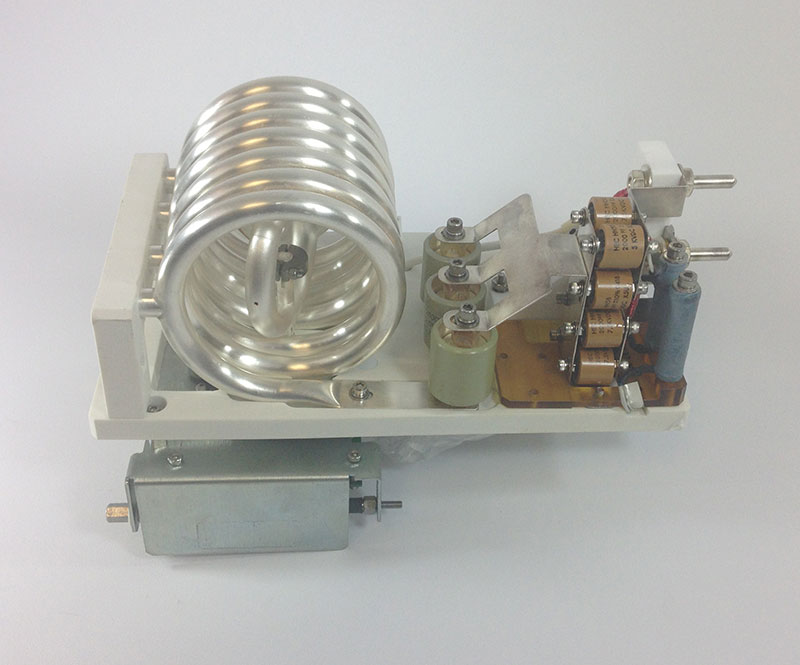

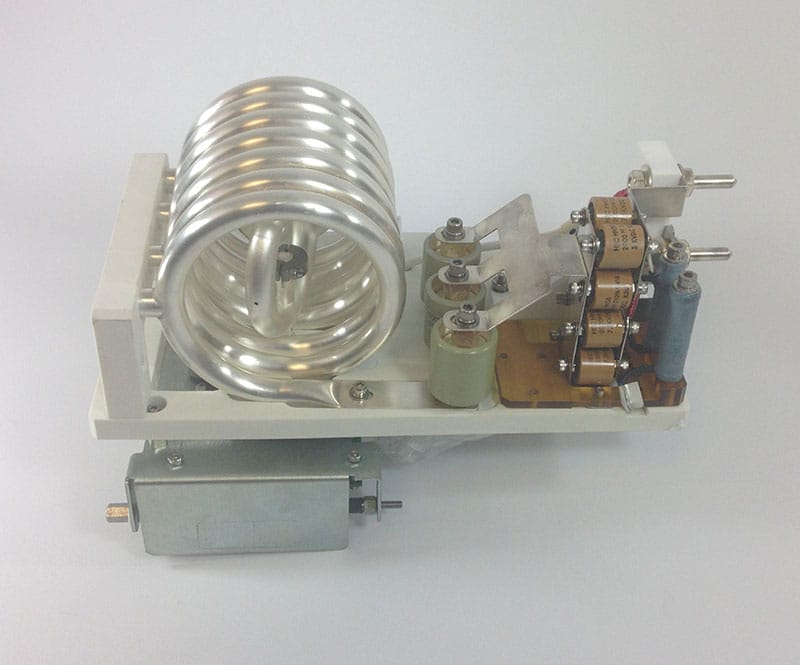

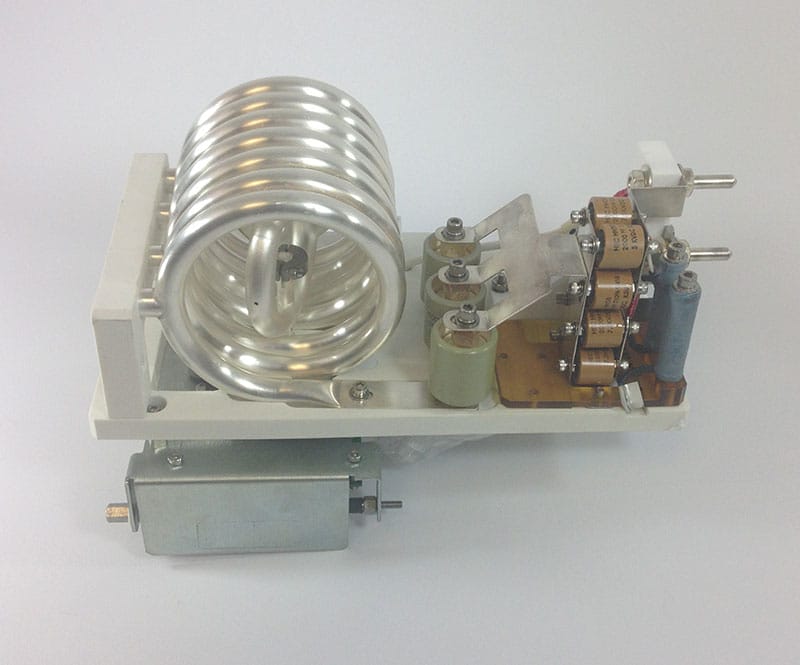

853-012175-001 Lam Research Harmonic Drive

853-012175-001 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

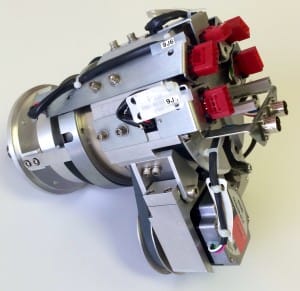

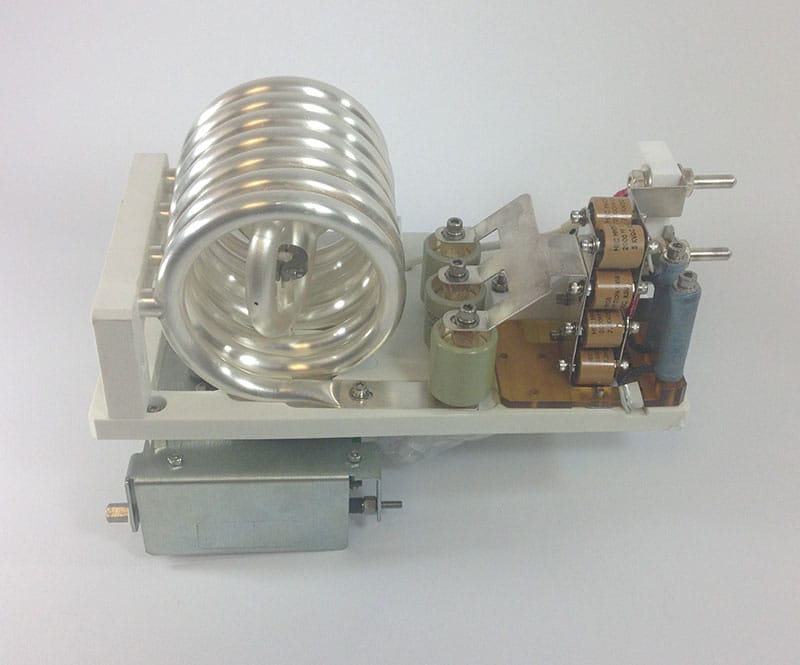

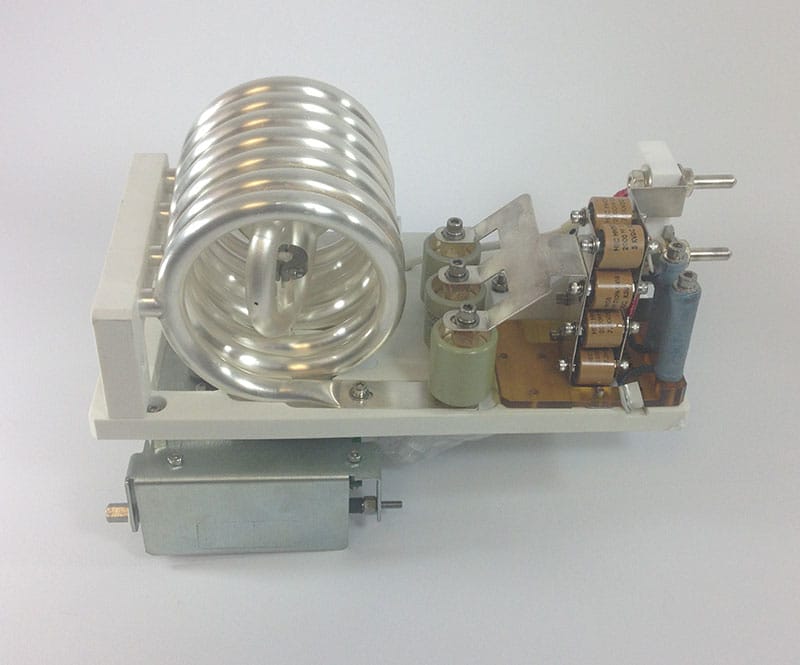

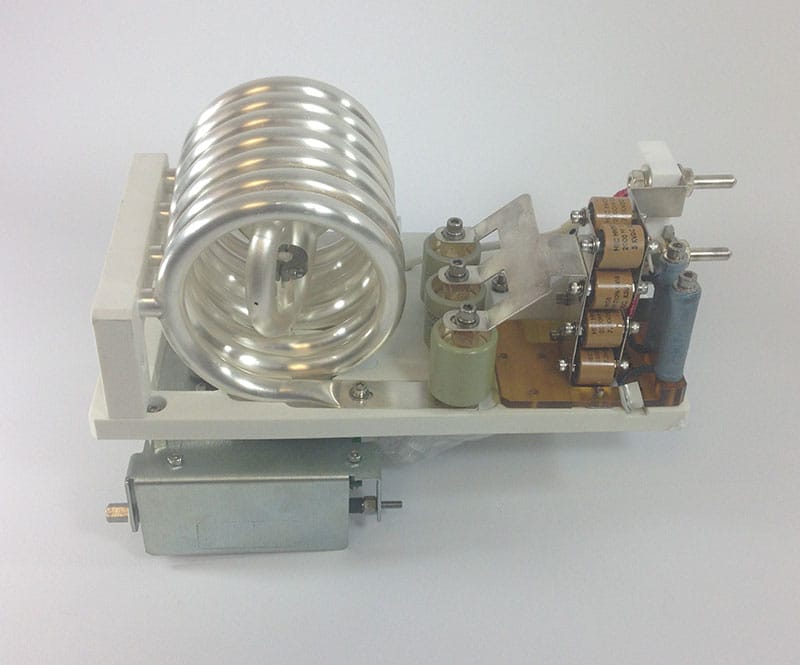

853-012175-002 Lam Research Harmonic Drive

853-012175-002 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

853-012175-003 Lam Research Harmonic Drive

853-012175-003 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

853-012175-004 Lam Research Harmonic Drive

853-012175-004 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

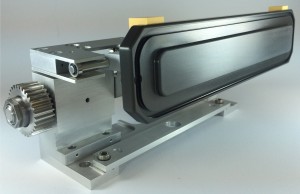

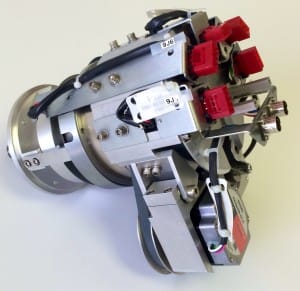

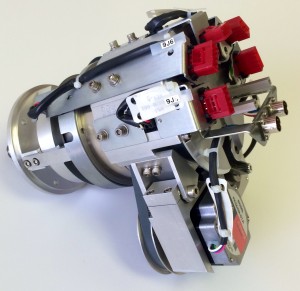

853-032776-002 Lam Research Paddle Lifter

853-032776-002 Lam Research Paddle Lifter

Download Datasheet

The Lam Research Paddle Lifter cycles the heated paddle up & down with precision.

Applications Include:

All Lam Research Standalone 4520i & 9600 platforms.

Features

- New Bellows Assembly

- New Silicon Bronze Linear Adjust Screw

- New Stepper Motor

- New Linear & Thrust Bearings

- New Thrust Washers

- New D-Sub or Viking Connectors

- Fully Disassembled

- All Parts Cleaned and Re-anodized as needed

- Helium Leak Tested

- Full Functionality Tested on an actual Lam machine

853-032776-605 Lam Research Paddle Lifter

853-032776-605 Lam Research Paddle Lifter

Download Datasheet

The Lam Research Paddle Lifter cycles the heated paddle up & down with precision.

Applications Include:

All Rainbow Standalone 4520i & 9600 platforms

Features

- New Bellows Assembly

- New Silicon Bronze Linear Adjust Screw

- New Stepper Motor

- New Linear & Thrust Bearings

- New Thrust Washers

- New D-Sub or Viking Connectors

- Fully Disassembled

- All Parts Cleaned and Re-anodized as needed

- Helium Leak Tested

- Full Functionality Tested on an actual Lam machine

853-021924-003 Lam Research Paddle Lifter

853-021924-003 Lam Research Paddle Lifter

Download Datasheet

The Lam Research Paddle Lifter cycles the heated paddle up & down with precision.

Applications Include:

All Lam Research Standalone 4520i & 9600 Platforms.

Features

- New Bellows Assembly

- New Silicon Bronze Linear Adjust Screw

- New Stepper Motor

- New Linear & Thrust Bearings

- New Thrust Washers

- New D-Sub or Viking Connectors

- Fully Disassembled

- All Parts Cleaned and Re-anodized as needed

- Helium Leak Tested

- Full Functionality Tested on an actual Lam machine

853-032776-001 Lam Research Paddle Lifter

853-032776-001 Lam Research Paddle Lifter

Download Datasheet

The Lam Research Paddle Lifter cycles the heated paddle up & down with precision accuracy.

Applications Include:

All Rainbow Standalone 4520i & 9600 Platforms.

Features

- New Bellows Assembly

- New Silicon Bronze Linear Adjust Screw

- New Stepper Motor

- New Linear & Thrust Bearings

- New Thrust Washers

- New D-Sub or Viking Connectors

- Fully Disassembled

- All Parts Cleaned and Re-anodized as needed

- Helium Leak Tested

- Full Functionality Tested on an actual Lam Machine

853-001198-002 AutoEtch Inner Gate Assembly

853-001198-002 AutoEtch Inner Gate Assembly

Download Datasheet

The AutoEtch Gate assembly is a precision mechanical isolation barrier between atmosphere/load locks & the main chamber of the AutoEtch. It is designed for repeatable precision wafer processing and will function flawlessly for thousands of cycles depending on process chemistry.

Applications Include:

All Lam Research Standalone AutoEtch 490, 590, 690 & 790 Platforms.

Features

- Brand New Gates

- Exchange & Refurbishing Services Available

- New Anodized Door

- New Gate Stops

- New Screws

- New Bearings

- New Bushings

- New Shims

- New Spring

- New Sprocket

- New Compression Fitting

- New Mounting Hub

- New Clevis

- New Roll Pins

- Full Functionality Tested

853-001198-001 AutoEtch Outer Gate Assembly

853-001198-001 AutoEtch Outer Gate Assembly

Download Datasheet

The AutoEtch Gate assembly is a precision mechanical isolation barrier between atmosphere/load locks & the main chamber of the AutoEtch. It is designed for repeatable precision wafer processing and will function flawlessly for thousands of cycles depending on process chemistry.

Applications Include:

All Lam Research Standalone AutoEtch 490, 590, 690 & 790 Platforms.

Features

- Brand New Gates Available

- Exchange & Refurbishing Services Available

- New Anodized Door

- New Gate Stops

- New Screws

- New Bearings

- New Bushings

- New Shims

- New Spring

- New Sprocket

- New Compression Fitting

- New Mounting Hub

- New Clevis

- New Roll Pins

- Full Functionality Tested

PTS03001UNIV Varian-Agilent TriScroll 300 Pump

PTS03001UNIV Varian-Agilent TriScroll 300 Pump

Download Datasheet

The TriScroll 300 series features two-stage dry scroll pumps that deliver high pumping speeds and low base pressure. TriScroll pumps feature proven reliability and durability, providing consistent performance and superior cost of ownership.

Features

Major Rebuild:

- Completely disassemble the pump module

- Completely clean all internal parts

- Install new tip seals and o-rings

- Assembly, Sync Crank Pins (3)

- Main crank shaft replaced as needed (at an additional cost)

- Remove all old bearings and replace with new bearings

- Perform bench test

- All Varian-Agilent TriScroll 300 pumps are tested to a base pressure of 10 millitorr or less

Standard Rebuild:

- Completely disassemble the pump module

- Completely clean all internal parts

- Pack bearings with high performance vacuum grease

- Install new tip seals and o-rings

- Perform bench test

- All Varian-Agilent TriScroll 300 pumps are tested to a base pressure of 10 millitorr or less

PTS06001UNIV Varian-Agilent TriScroll 600 Pump

PTS06001UNIV Varian-Agilent TriScroll 600 Pump

Download Datasheet

The TriScroll 600 series features two-stage dry scroll pumps that deliver high pumping speeds and low base pressure. TriScroll pumps feature proven reliability and durability, providing consistent performance and superior cost of ownership.

Major Rebuild:

- Completely disassemble the pump module

- Completely clean all internal parts

- Install new tip seals and o-rings

- Assembly, Sync Crank Pins (3)

- Main crank shaft replaced as needed (at an additional cost)

- Remove all old bearings and replace with new bearings

- Perform bench test

- All Varian-Agilent TriScroll 600 pumps are tested to a base pressure of 10 millitorr or less

Standard Rebuild:

- Completely disassemble the pump module

- Completely clean all internal parts

- Pack bearings with high performance vacuum grease

- Install new tip seals and o-rings

- Perform bench test

- All Varian-Agilent TriScroll 600 pumps are tested to a base pressure of 10 millitorr or less

853-012200-002 Lam Research Gate Drive Inner Assembly

853-012200-002 Lam Research Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-012200-004 Lam Research 9600 Gate Drive Inner Assembly

853-012200-004 Lam Research 9600 Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-012261-001 Lam Research Gate Drive Inner Assembly

853-012261-001 Lam Research Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-012875-002 Lam Research 9600 Gate Drive Inner Assembly

853-012875-002 Lam Research 9600 Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-012875-001 Lam Research Gate Drive Inner Assembly

853-012875-001 Lam Research Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-012100-003 Lam Research Arm Housing Assembly

853-012100-003 Lam Research Arm Housing Assembly

Download Datasheet

The Lam Research Arm Housing Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- Fully Disassembled

- All Parts Cleaned

- New Bearings

- New Screws

- New Spindle As Needed

- New Extension Spring As Needed

- New Drive Cable As Needed

- Arm Housing Cover Helium Leak Checked

- Full Functionality Tested on an Actual Lam Rainbow Tool for Parallelism & Repeatability

853-012100-001 Lam Research Arm Housing Assembly

853-012100-001 Lam Research Arm Housing Assembly

Download Datasheet

The Lam Research Arm Housing Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- Fully Disassembled

- All Parts Cleaned

- New Bearings

- New Screws

- New Spindle As Needed

- New Extension Spring As Needed

- New Drive Cable As Needed

- Arm Housing Cover Helium Leak Checked

- Full Functionality Tested on an Actual Lam Rainbow Tool for Parallelism & Repeatability

853-012100-004 Lam Research Arm Housing Assembly

853-012100-004 Lam Research Arm Housing Assembly

Download Datasheet

The Lam Research Arm Housing Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- Fully Disassembled

- All Parts Cleaned

- New Bearings

- New Screws

- New Spindle As Needed

- New Extension Spring As Needed

- New Drive Cable As Needed

- Arm Housing Cover Helium Leak Checked

- Full Functionality Tested on an Actual Lam Rainbow Tool for Parallelism & Repeatability

853-442064-002 LAM Research Gate Drive Inner Assembly

853-442064-002 LAM Research Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

853-442078-001 Lam Research Gate Drive Inner Assembly

853-442078-001 Lam Research Gate Drive Inner Assembly

Download Datasheet

The Lam Research Gate Drive Inner Assembly is used on All Rainbow Standalone Platforms as well as some Alliance Multi-Chamber Platforms.

The Lam Research Gate Drive Inner Assembly cycles up & down with precision accuracy isolating the main chamber from the load locks, it also provides a vacuum tight seal for process etch isolation and safe wafer transport.

Features

- Fully Disassembled

- All Parts Cleaned

- New Sensors

- New Pneumatic Air Cylinders

- New Pneumatic Air Fittings

- New Pneumatic Air Lines

- New Cam Followers

- New Bumpers for Link

- Labeled

- Over-lock Adjustment

- Flag Interrupt Adjustment

- Full Functionality Tested on an Actual Lam Rainbow Tool

- ***Gate Drive Link Replaced or Upgraded with Newer Robust Version as Needed***

C-2134-086-0001 Ebara Rotary Union

C-2134-086-0001 Ebara Rotary Union

Download Datasheet

Semigroup offers service and support for various OEM CMP sub-assemblies.

Features

- Fully Disassembled

- All Parts Cleaned

- Lap & Polish All Carbide Pieces

- Install New Springs, O-rings, Bearings, and Seals

- Re-grease As Needed

- Re-assemble to OEM Spec

- Pressure Test That Assembly is Leak Tight

- New Carbide Pieces Made As Needed

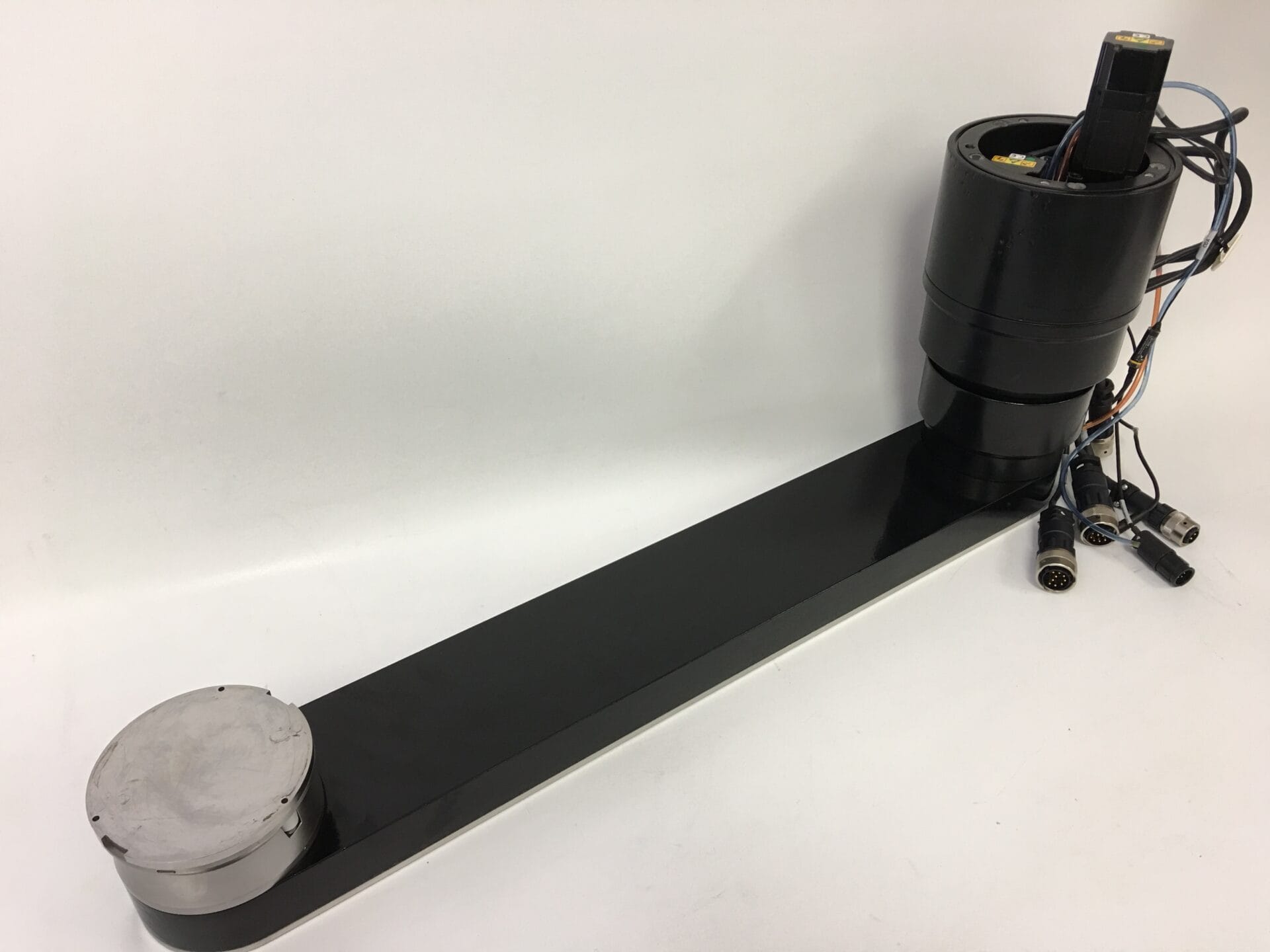

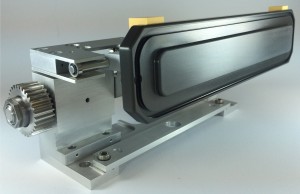

852-011060-001 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive)

852-011060-001 | Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive)

Download Datasheet

Lam Research Rainbow Assembly Housing Upper Chamber (Rainbow Gap Drive) provides highly reliable movement under low pressure.

Applications Include:

4400, 4500, 4520, 4520i Rainbow Standalone Platforms

Features

- New Idler Sprockets

- New Bearings for Idler Sprockets

- New Bearings for Housing, Gap Adjust

- New Chain #25

- New Plate, Bearing Mount (Plate Bearing Mount Stainless Steel Plates are measured for flatness and Replaced if bent or warped).

- New Shoulder Screws

- Refurbished Lead Screws (1-Driver and 3-Driven are all refurbished with new internal parts, properly lubricated, including brand new Sprockets).

- Hard Stops are set up

- Quad Seal Ring (Cleaned up and sent back with Gap Barrel Housing for easy installation on your Rainbow Tool.

- Parallelism is checked and set up for minimal adjustment.

- All final testing is completed on a LAM Research Tool.

853-012123-500 Lam Research Harmonic Drive

853-012123-500 Lam Research Harmonic Drive

Download Datasheet

The Lam Research Harmonic Arm Drive Assembly provides highly reliable and repeatable wafer placement.

Applications Include:

All Rainbow Standalone Platforms

Features

- New Belts

- New Bearings

- New Quad Seals

- New O-rings

- New Sensors

- New Stepper Motors

- New Connectors (Metal or Viking)

- New Wiring

- New Pins

- Custom Labeled

- Fully Disassembled

- All Parts Cleaned

- Full Functionality Tested on an Actual Lam Rainbow Tool

- New Harmonic Core Replacement Installed To Address Wafer Handling Issues (Picture Below)

0010-25303 | Applied Materials 300MM LK Pad Conditioner Arm

0010-25303 | Applied Materials 300MM LK Pad Conditioner Arm

Download Datasheet

Applied Materials 300MM LK Pad Conditioner Arm

Features

- New Bearings

- New O-rings

- Fully Disassembled

- All Parts Cleaned

- Harmonic Drive, Wave Generator, Flex Spline, Circular Spline (Disassemble and inspect, clean, regrease and reassemble).

- All Fasteners Replaced

- Test and Check Servo Motors (Repair If needed).

- Powder Coating Service

- Sensor Replacement

- Boot Replacement

0010-12313 | Applied Materials 300MM HVM Reflexion Pad Conditioner Arm

0010-12313 | Applied Materials 300MM HVM Reflexion Pad Conditioner Arm

Download Datasheet

Applied Materials 300MM HVM Reflexion Pad Conditioner Arm

Features

- New Bearings

- New O-Rings

- Fully Disassembled

- All Parts Cleaned

- Harmonic Drive, Wave Generator, Flex Spline, Circular Spline (Disassemble and inspect, clean, regrease and reassemble).

- All Fasteners Replaced

- Test and Check Servo Motors (Repair if needed).

- Powder Coating Service

- Sensor Replacement

- Boot Replacement

853-012500-003 | Edge Sensor Assembly

853-012500-003 | Edge Sensor Assembly

Download Datasheet

Edge Sensor Assembly

Features

- New Fiber Optic Amplifier

- New Fiber Optics X 2

- New Stepper Motor

- New Viking or Misumi Connectors

- Fully Disaasemble

- All Parts Cleaned

- Full Functionality Tested on actual Lam Machine

- New Opto isolator

SG660-091821-001 | Semigroup Engineered **New** Drop in Replacement for Lam Power Supply 660-091821-001, +5, +15, -15

SG660-091821-001 | Semigroup Engineered **New** Drop in Replacement for Lam Power Supply 660-091821-001, +5, +15, -15

Download Datasheet

Semigroup **New** Drop in Replacement (Engineered by Semigroup) for Lam Research Power Supply 660-091821-001, +5, +15, -15

Features

- Mounting Bracket installed on Power Supply

- All Wire Connection are Compatible with Lam Tools

- Voltage Sense on 5V 40 AMP

- CE Certification Included

- Red & Black Color Terminals for Easy Installation

- Full Functionality Tested on an Actual Lam Tool -002 AC/DC Box

SG660-091820-001 | Semigroup** New** Drop in replacement (Engineered by Semigroup) for Lam Research Power Supply 660-091820-001

SG660-091820-001 | Semigroup** New** Drop in replacement (Engineered by Semigroup) for Lam Research Power Supply 660-091820-001

Download Datasheet

Semigroup** New** Drop in replacement (Engineered by Semigroup) for Lam Research Power Supply 660-091820-001

Features

- Mounting Bracket Installed on Power Supply

- All Wire Connection are Compatible with Lam Tools

- Voltage Inhibit Works with Lam 24 Volt Actuator Switch

- EC Certification Included

- Red and Black Terminals for Easy Installation

- Full Functionality Test on an Actual Lam Tool -002 AC/DC Box

853-012500-002| Edge Sensor Assembly

853-012500-002| Edge Sensor Assembly

Download Datasheet

Edge Sensor Assembly

Features

- New Fiber Optic Amplifier

- New Fiber Optics X 2

- New Stepper Motor

- New Viking or Misumi Connectors

- Fully Disaasemble

- All Parts Cleaned

- Full Functionality Tested on actual Lam Machine

- New Opto isolator

INR-244-215A | SMC Chiller

INR-244-215A | SMC Chiller

Download Datasheet

INR-244-215A SMC Chiller

Features

- Pump replaced

- Replace hoses

- Replace water

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

INR-244-117A | SMC Chiller

INR-244-117A | SMC Chiller

Download Datasheet

INR-244-217A SMC Chiller

Features

- Pump replaced

- Reseal water tank

- Replace hoses

- Replace water lines

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

INR-244-117C | SMC Chiller

INR-244-117C | SMC Chiller

Download Datasheet

INR-244-217C SMC Chiller

Features

- Pump replaced

- Reseal water tank

- Replace hoses

- Replace water lines

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

INR-244-112 | SMC Chiller

INR-244-112 | SMC Chiller

Download Datasheet

INR-244-112 SMC Chiller

Features

- Pump replaced

- Reseal water tank

- Replace hoses

- Replace water lines

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

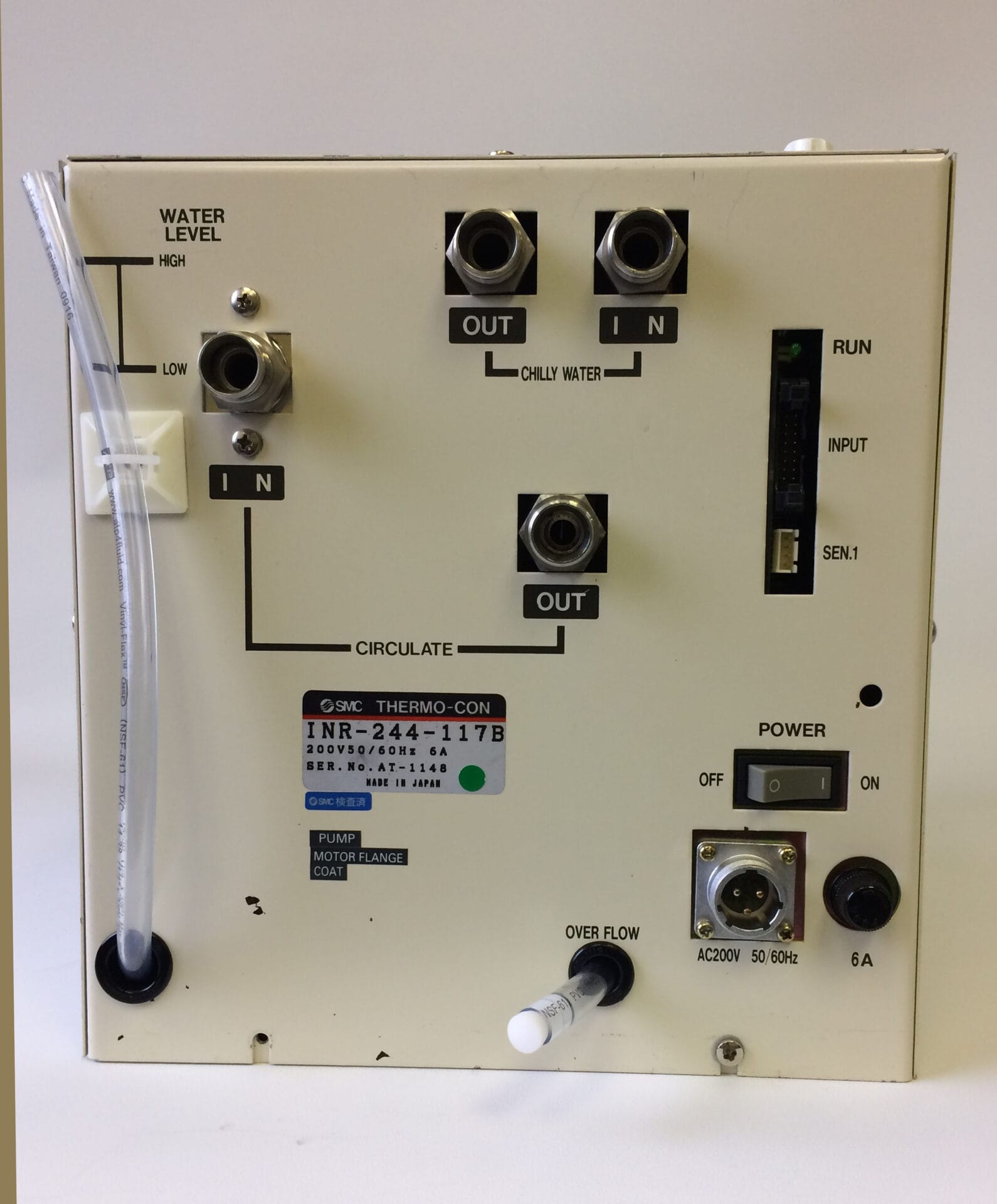

INR-244-117B | SMC Chiller

INR-244-117B | SMC Chiller

Download Datasheet

INR-244-117B SMC Chiller

Features

- Pump replaced

- Reseal water tank

- Replace hoses

- Replace water lines

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

INR-244-602A | SMC Chiller

INR-244-602A | SMC Chiller

Download Datasheet

INR-244-602A | SMC Chiller

Features

- Pump replaced

- Reseal water tank

- Replace hoses

- Replace water lines

- Rebuild thermo module with new peltiers

- Replace other parts as needed

- Run chiller and cycle for temperature and flow control

242-027-0142 | Electrocraft E242 Servo Motor

242-027-0142 | Electrocraft E242 Servo Motor

Download Datasheet

242-027-0142 | Electrocraft E242 Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

0190-14344W-R | NSK Motor & Controller Set Service

0190-14344W-R | NSK Motor & Controller Set Service

Download Datasheet

0190-14344W-R | NSK Motor & Controller Set Service

Features

- Disassemble the NSK Motor.

- All internal parts including windings, contacts, bearing clamp and rotor are inspected for damage or physical wear.

- Motor is cleaned of any old broken down grease or metal debris from the old failed bearing.

- Install new connectors, seals and bearings with OEM grease.

- Disassemble the Controller.

- Full visual inspection is done.

- Replace any defective parts.

- Change all electrolytic capacitors.

- Repair solder connections and reflow solder as required.

- Mate power supply to logic board and test basic fault circuits.

- Bench test drive the drive modules and check output phasing.

- Reassemble drive and bench test.

- Check fault circuits and communications.

- Tune controller to motor and complete final motor test.

- Reset internal switches to customer settings.

- Please see our “Product Categories” for custom cases to protect your NSK Motor & Controller.

0190-14344-R | NSK Motor & Controller Set Service

0190-14344-R | NSK Motor & Controller Set Service

Download Datasheet

0190-14344-R | NSK Motor & Controller Set Service

Features

- Disassemble the NSK Motor.

- All internal parts including windings, contacts, bearing clamp and rotor are inspected for damage or physical wear.

- Motor is cleaned of any old broken down grease or metal debris from the old failed bearing.

- Install new connectors, seals and bearings with OEM grease.

- Disassemble the Controller.

- Full visual inspection is done.

- Replace any defective parts.

- Change all electrolytic capacitors.

- Repair solder connections and reflow solder as required.

- Mate power supply to logic board and test basic fault circuits.

- Bench test drive the drive modules and check output phasing.

- Reassemble drive and bench test.

- Check fault circuits and communications.

- Tune controller to motor and complete final motor test.

- Reset internal switches to customer settings.

- Please see our “Product Categories” for custom cases to protect your NSK Motor & Controller.

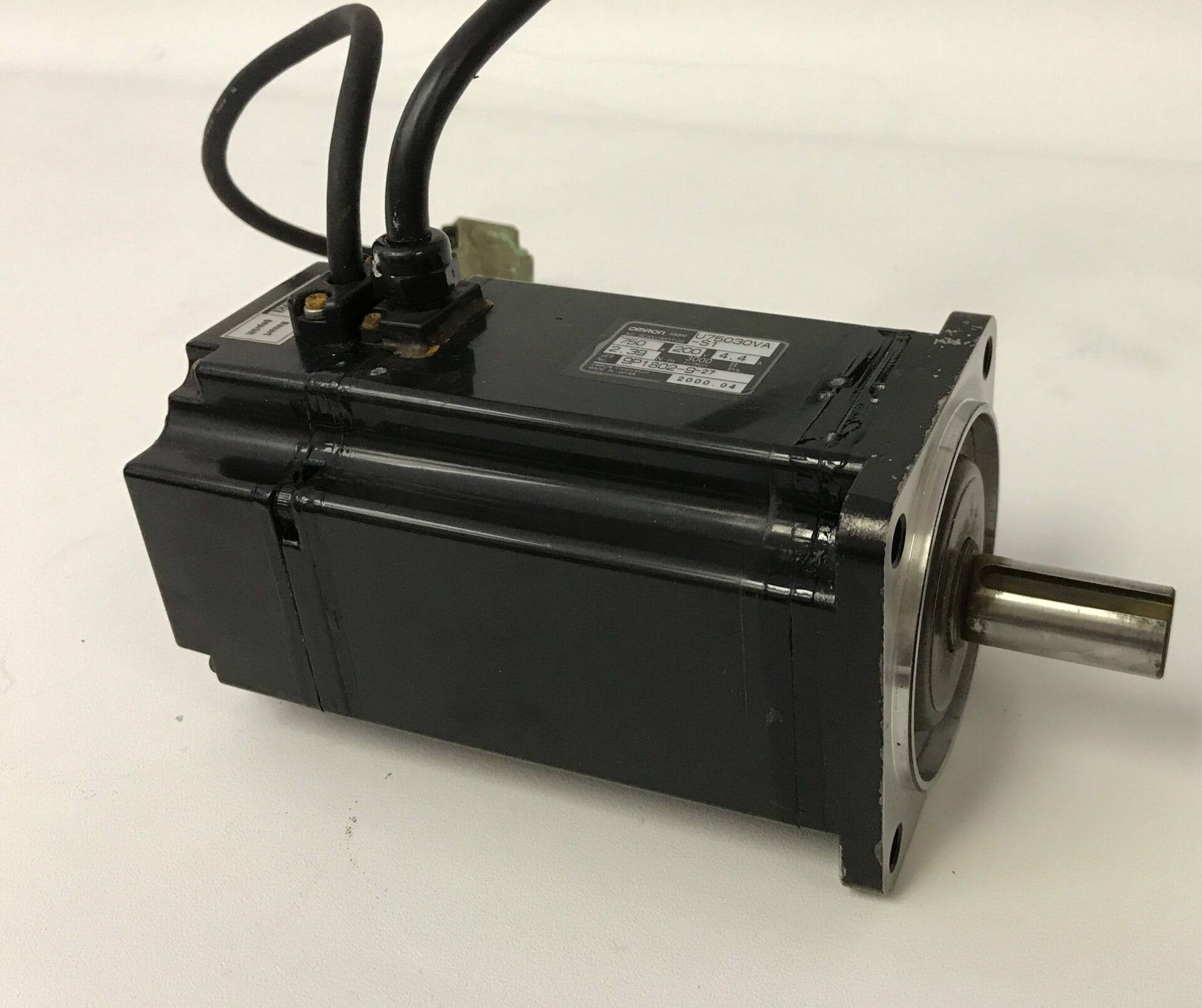

R88M-U75030VA-S1 | OMRON AC Servo Motor

R88M-U75030VA-S1 | OMRON AC Servo Motor

Download Datasheet

R88M-U75030VA-S1 | OMRON AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

HC-MF23G1-UE | Mitsubishi AC Servo Motor

HC-MF23G1-UE | Mitsubishi AC Servo Motor

Download Datasheet

HC-MF23G1-UE | Mitsubishi AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

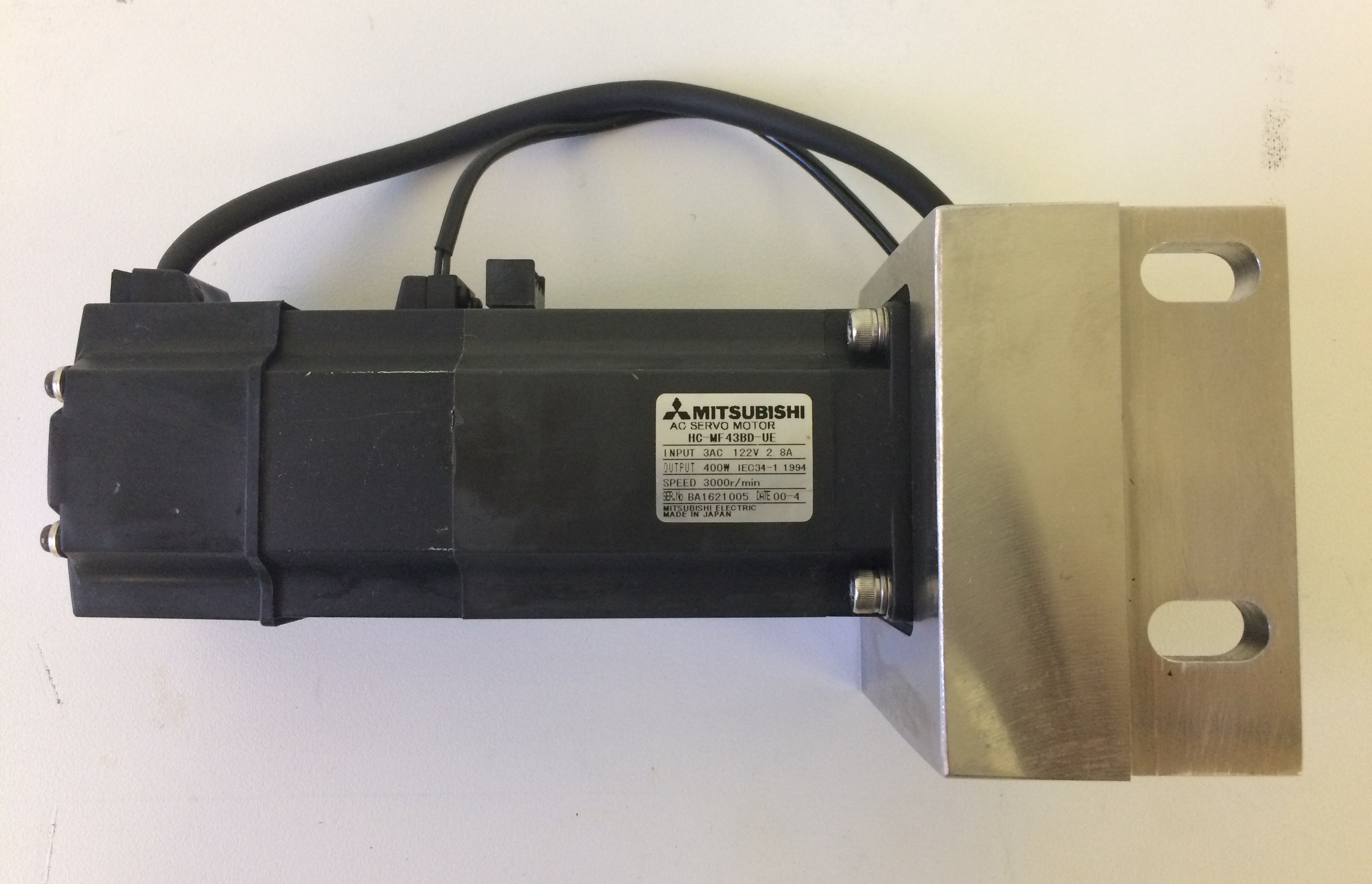

HC-MF43BD-UE | Mitsubishi AC Servo Motor

HC-MF43BD-UE | Mitsubishi AC Servo Motor

Download Datasheet

HC-MF43BD-UE | Mitsubishi AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

830003428 | Maxon Servo Motor

830003428 | Maxon Servo Motor

Download Datasheet

830003428 | Maxon Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

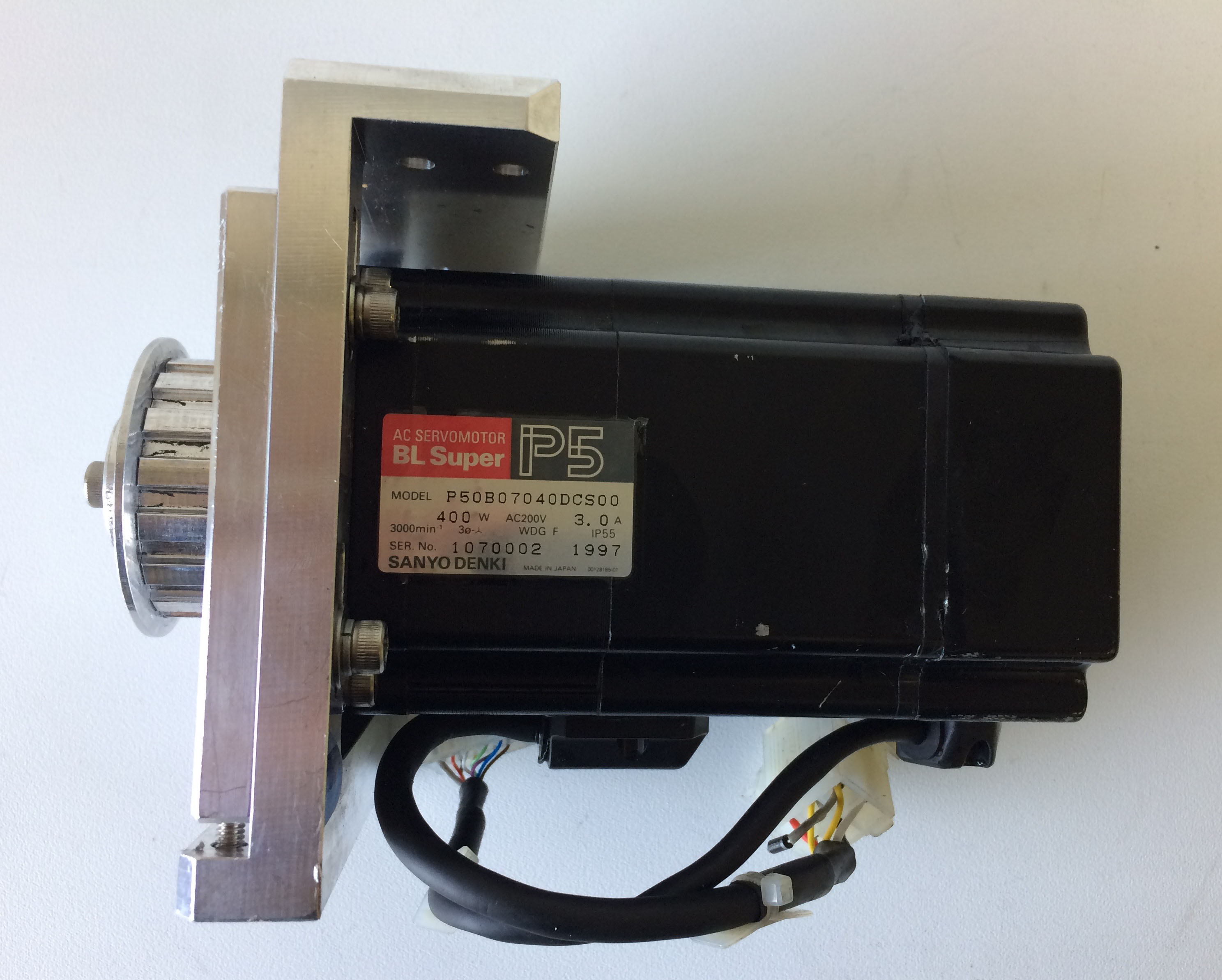

P50B07040DCS00 | Sanyo Denki AC Servo Motor BL Super P5

P50B07040DCS00 | Sanyo Denki AC Servo Motor BL Super P5

Download Datasheet

P50B07040DCS00 | Sanyo Denki AC Servo Motor BL Super P5

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P10B13100BCS23 | Sanyo Denki AC Servo Motor

P10B13100BCS23 | Sanyo Denki AC Servo Motor

Download Datasheet

P10B13100BCS23 | Sanyo Denki AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P50B03003DXS00 | Sanyo Denki AC Servo Motor

P50B03003DXS00 | Sanyo Denki AC Servo Motor

Download Datasheet

P50B03003DXS00 | Sanyo Denki AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P50B05005DXS00 | Sanyo Denki AC Servo Motor

P50B05005DXS00 | Sanyo Denki AC Servo Motor

Download Datasheet

P50B05005DXS00 | Sanyo Denki AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P50B05010DCS00 | Sanyo Denki AC Servo Motor

P50B05010DCS00 | Sanyo Denki AC Servo Motor

Download Datasheet

P50B05010DCS00 | Sanyo Denki AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMS-20A6AB | Yaskawa AC Servo Motor

SGMS-20A6AB | Yaskawa AC Servo Motor

Download Datasheet

SGMS-20A6AB | Yaskawa AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

HC-MF23BG1D-UE | Mitsubishi AC Servo Motor

HC-MF23BG1D-UE | Mitsubishi AC Servo Motor

Download Datasheet

HC-MF23BG1D-UE | Mitsubishi AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

R02SAKOE UTOPI-200SE | Yaskawa Minertia DC Servo Motor

R02SAKOE UTOPI-200SE | Yaskawa Minertia DC Servo Motor

Download Datasheet

R02SAKOE UTOPI-200SE | Yaskawa Minertia DC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMAH-01AAAP18 | Yaskawa AC Servo Motor

SGMAH-01AAAP18 | Yaskawa AC Servo Motor

Download Datasheet

SGMAH-01AAAP18 | Yaskawa AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMAH-01AAF41 | Yaskawa AC Servo Motor

SGMAH-01AAF41 | Yaskawa AC Servo Motor

Download Datasheet

SGMAH-01AAF41 | Yaskawa AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

HC-MF23BK-UE | Mitsubishi AC Servo Motor

HC-MF23BK-UE | Mitsubishi AC Servo Motor

Download Datasheet

HC-MF23BK-UE | Mitsubishi AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMS-50A6AB | Yaskawa AC Servo Motor

SGMS-50A6AB | Yaskawa AC Servo Motor

Download Datasheet

SGMS-50A6AB | Yaskawa AC Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P50B05010DCL68 | Sanyo Denki Servo Motor

P50B05010DCL68 | Sanyo Denki Servo Motor

Download Datasheet

P50B05010DCL68 | Sanyo Denki Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMPH-04AAE41D | Yaskawa Servo Motor

SGMPH-04AAE41D | Yaskawa Servo Motor

Download Datasheet

SGMPH-04AAE41D | Yaskawa Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMP-02U314M | Yaskawa Servo Motor

SGMP-02U314M | Yaskawa Servo Motor

Download Datasheet

SGMP-02U314M | Yaskawa Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGM-02A3YB11 | Yaskawa Servo Motor

SGM-02A3YB11 | Yaskawa Servo Motor

Download Datasheet

SGM-02A3YB11 | Yaskawa Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGM-02U3B4L | Yaskawa Servo Motor

SGM-02U3B4L | Yaskawa Servo Motor

Download Datasheet

SGM-02U3B4L | Yaskawa Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

P60B18750RXS00M | Sanyo Denki Servo Motor

P60B18750RXS00M | Sanyo Denki Servo Motor

Download Datasheet

P60B18750RXS00M | Sanyo Denki Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

SGMP-01U314M | Yaskawa Servo Motor

SGMP-01U314M | Yaskawa Servo Motor

Download Datasheet

SGMP-01U314M | Yaskawa Servo Motor

Features

- Visual inspection of Servo Motor.

- Rotate the shaft forward and reverse.

- Meg the motor.

- Use Mitchell Electronic test equipment to check the alignment of the feedback, perform a KE test and check the function of feedback including resolver angles, encoder and tach voltages.

- If encoder is damaged it is then replaced with a new encoder.

- Disassemble and clean the Servo Motor.

- Perform the surge and hipot test.

- Reassemble Servo Motor.

- Replace bearings and seals.

- Align feedback

- Perform final bench test on our test equipment.

1080-00036 | NSK Motor Service

1080-00036 | NSK Motor Service

Download Datasheet

1080-00036| NSK Motor Service

Features

- Disassemble the NSK Motor.

- All internal parts including windings, contacts, bearing clamp and rotor are inspected for damage or physical wear.

- Motor is cleaned of any old broken down grease or metal debris from the old failed bearing.

- Install new connectors, seals and bearings with OEM grease.

- Tune controller to motor and complete final motor test.

RZ0810FN507 | NSK Motor Service

RZ0810FN507 | NSK Motor Service

Download Datasheet

RZ0810FN507| NSK Motor Service

Features

- Disassemble the NSK Motor.

- All internal parts including windings, contacts, bearing clamp and rotor are inspected for damage or physical wear.

- Motor is cleaned of any old broken down grease or metal debris from the old failed bearing.

- Install new connectors, seals and bearings with OEM grease.

- Tune controller to motor and complete final motor test.

EP0810AF5-05 | NSK Controller

EP0810AF5-05 | NSK Controller

Download Datasheet

EP0810AF5-05 | NSK Controller

Features

- Disassemble the Controller.

- Full visual inspection is done.

- Replace any defective parts.

- Change all electrolytic capacitors.

- Repair solder connections and reflow solder as required.

- Mate power supply to logic board and test basic fault circuits.

- Bench test drive the drive modules and check output phasing.

- Reassemble drive and bench test.

- Check fault circuits and communications.

- Tune controller to motor and complete final motor test.

- Reset internal switches to customer settings.

EP0810AF8-05 | NSK Controller

EP0810AF8-05 | NSK Controller

Download Datasheet

EP0810AF8-05 | NSK Controller

Features

- Disassemble the Controller.

- Full visual inspection is done.

- Replace any defective parts.

- Change all electrolytic capacitors.

- Repair solder connections and reflow solder as required.

- Mate power supply to logic board and test basic fault circuits.

- Bench test drive the drive modules and check output phasing.

- Reassemble drive and bench test.

- Check fault circuits and communications.

- Tune controller to motor and complete final motor test.

- Reset internal switches to customer settings.

DR303AE9MA| Ametek Rotron Regenerative Blower

DR303AE9MA| Ametek Rotron Regenerative Blower

Download Datasheet

DR303AE9MA| Ametek Rotron Regenerative Blower

Features

- Replace bearings

- Visual Inspection of Stator and Rotor

- Starter cap dielectric isolation components replaced

- Tap/Rethread damaged bolt holes

- Repair stripped holes and insert helicoils

- Post repair electrical operation/functional test

- Electro mechanical operational verification

810-017086-018 | ESC Power Supply

810-017086-018 | ESC Power Supply

Download Datasheet

810-017086-018 | ESC Power Supply

Features

- Visual inspection of PCB

- Initial bench testing assessment

- Standard electronic components replaced as follows:

- *Fuses

- *Mechanical Relays

- *Zener diodes

- *Resistors

- *OP amplifiers

- *Capacitors

- Output voltage calibrated

- Post repair electrical functionality and operational test

810-017086-007 | ESC Power Supply

810-017086-007 | ESC Power Supply

Download Datasheet

810-017086-007 | ESC Power Supply

Features

- Visual inspection of PCB

- Initial bench testing assessment

- Standard electronic components replaced as follows:

- *Fuses

- *Mechanical Relays

- *Zener diodes

- *Resistors

- *OP amplifiers

- *Capacitors

- Output voltage calibrated

- Post repair electrical functionality and operational test

810-017086-008 | ESC Power Supply

810-017086-008 | ESC Power Supply

Download Datasheet

810-017086-008 | ESC Power Supply

Features

- Visual inspection of PCB

- Initial bench testing assessment

- Standard electronic components replaced as follows:

- *Fuses

- *Mechanical Relays

- *Zener diodes

- *Resistors

- *OP amplifiers

- *Capacitors

- Output voltage calibrated

- Post repair electrical functionality and operational test

810-017086-010 | ESC Power Supply

810-017086-010 | ESC Power Supply

Download Datasheet

810-017086-010 | ESC Power Supply

Features

- Visual inspection of PCB

- Initial bench testing assessment

- Standard electronic components replaced as follows:

- *Fuses

- *Mechanical Relays

- *Zener diodes

- *Resistors

- *OP amplifiers

- *Capacitors

- Output voltage calibrated

- Post repair electrical functionality and operational test

810-370182-001 | Lam Research Assembly, PCB, ESC Power Supply, DTRBD

810-370182-001 | Lam Research Assembly, PCB, ESC Power Supply, DTRBD

Download Datasheet

810-370182-001 | Lam Research Assembly, PCB, ESC Power Supply, DTRBD

Features

- Visual inspection of PCB

- Initial bench testing assessment

- Standard electronic components replaced as follows:

- *Fuses

- *Mechanical Relays

- *Zener diodes

- *Resistors

- *OP amplifiers

- *Capacitors

- Output voltage calibrated

- Post repair electrical functionality and operational test

683-24562 | MKS Throttle Valve

683-24562 | MKS Throttle Valve

Download Datasheet

683-24562 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

253B-24836 | MKS Throttle Valve

253B-24836 | MKS Throttle Valve

Download Datasheet

253B-24836 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

153D-15006 | MKS Throttle Valve

153D-15006 | MKS Throttle Valve

Download Datasheet

153D-15006 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

253B-1-40-1 | MKS Throttle Valve

253B-1-40-1 | MKS Throttle Valve

Download Datasheet

253B-1-40-1 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

153D-2-50-2 | MKS Throttle Valve

153D-2-50-2 | MKS Throttle Valve

Download Datasheet

153D-2-50-2 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

153D-12018 | MKS Throttle Valve

153D-12018 | MKS Throttle Valve

Download Datasheet

153D-12018 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

283152 | MKS Throttle Valve

283152 | MKS Throttle Valve

Download Datasheet

283152 | MKS Throttle Valve

Features

- Replace and rewire motor

- Replace o’ring seals

- Replace bearings

- Replace throttle valve cam and bushings

- Replace valve lever

- Replace springs

- Replace limit switches

- Helium leak tested

- Manual and automatic pressure control function testing ranging from 0.5 Torr – 10 Torr

B65351000 | GVI 100P Edwards Isolation Valve

B65351000 | GVI 100P Edwards Isolation Valve

Download Datasheet

B65351000 | GVI 100P Edwards Isolation Valve

Features

- Decontamination cleaning

- O’Rings replaced

- Lubrication of lead screw and turn handle mechanics

- Bearings, guide wheels cleaned and replaced as needed

- Washers/spacers replaced

- Valve reassembled to OEM specifications

- Bellows replaced as needed

- Helium Leak Check

- Compression plate rebuilt when necessary

B65401000 | GVI 160M Edwards Isolation Valve

B65401000 | GVI 160M Edwards Isolation Valve

Download Datasheet

B65401000 | GVI 160M Edwards Isolation Valve

Features

- Decontamination cleaning

- O’Rings replaced

- Lubrication of lead screw and turn handle mechanics

- Bearings, guide wheels cleaned and replaced as needed

- Washers/spacers replaced

- Valve reassembled to OEM specifications

- Bellows replaced as needed

- Helium Leak Check

- Compression plate rebuilt when necessary

B65301000 | GVI 100M Edwards Isolation Valve

B65301000 | GVI 100M Edwards Isolation Valve

Download Datasheet

B65301000 | GVI 100M Edwards Isolation Valve

Features

- Decontamination cleaning

- O’Rings replaced

- Lubrication of lead screw and turn handle mechanics

- Bearings, guide wheels cleaned and replaced as needed

- Washers/spacers replaced

- Valve reassembled to OEM specifications

- Bellows replaced as needed

- Helium Leak Check

- Compression plate rebuilt when necessary

09140-PE01 | VAT Gate Valve Manual

09140-PE01 | VAT Gate Valve Manual

Download Datasheet

09140-PE01 | VAT Gate Valve Manual

Features

- Decontamination cleaning

- O’Rings replaced

- Lubrication of lead screw and turn handle mechanics

- Bearings, guide wheels cleaned and replaced as needed

- Washers/spacers replaced

- Valve reassembled to OEM specifications

- Bellows replaced as needed

- Helium Leak Check

- Compression plate rebuilt when necessary

- Use OEM parts to rebuild and refurbish valve

02-177392-00 | Novellus Platen Rebuild

02-177392-00 | Novellus Platen Rebuild

Download Datasheet

02-177392-00 | Novellus Platen Rebuild

Features

- Break down Platen

- Remove screws and clean disassembled parts

- Tap all screw holes

- Replace all screws

- Replace o’rings and pins

- Reassemble Platen

0750-700176 | Novellus 676 Main Cylinder Assembly

0750-700176 | Novellus 676 Main Cylinder Assembly

Download Datasheet

0750-700176 | Novellus 676 Main Cylinder Assembly

Features

- Break down cylinder

- Clean all parts

- Remove old grease

- Replace o’rings and seals

- Re-grease o’rings and seals

- Build up cylinder and leak test to specifications

0750-111515 | Novellus Momentum Main Cylinder Assembly

0750-111515 | Novellus Momentum Main Cylinder Assembly

Download Datasheet

0750-111515 | Novellus Momentum Main Cylinder Assembly

Features

- Break down cylinder

- Clean all parts and remove old grease

- Replace all seals and o’rings

- Re-grease o’rings, seals and parts

- Reassemble cylinder

- Leak test assembly to meet specifications

853-250001-121 | LAM Research RF Mini-Match

853-250001-121 | LAM Research RF Mini-Match

Download Datasheet

853-250001-121 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-250001-024 | LAM Research RF Mini-Match

853-250001-024 | LAM Research RF Mini-Match

Download Datasheet

853-250001-024 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-250001-023 | Lam Research RF Mini-Match (ASSY, RF MATCH, ESC PK D)

853-250001-023 | Lam Research RF Mini-Match (ASSY, RF MATCH, ESC PK D)

Download Datasheet

853-250001-023 | Lam Research RF Mini-Match (ASSY, RF MATCH, ESC PK D)

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-250001-021 | LAM Research RF Mini-Match

853-250001-021 | LAM Research RF Mini-Match

Download Datasheet

853-250001-021 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-330951-001 | LAM Research RF Mini-Match

853-330951-001 | LAM Research RF Mini-Match

Download Datasheet

853-330951-001 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-015130-503| LAM Research RF Mini-Match

853-015130-503| LAM Research RF Mini-Match

Download Datasheet

853-015130-503| LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-330951-021 | LAM Research RF Mini-Match

853-330951-021 | LAM Research RF Mini-Match

Download Datasheet

853-330951-021 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power

- Back side helium@ 10T pressure

- Communication to tool is verified

853-025083-022 | LAM Research RF Mini-Match

853-025083-022 | LAM Research RF Mini-Match

Download Datasheet

853-025083-022 | LAM Research RF Mini-Match

Features

- Fully Disassembled

- All parts cleaned

- New Motors

- New Potentiometers

- New Capacitors as required

- All RF Silver-plated components are restored to original specifications

- New hex mounting screws

- Replace gears as required

- New grounding wires

- Test and calibrate RF peak detect board

- Full functionality tested on an actual LAM Rainbow tool.

- Verify RF Plasma is confined with zero watts reflected power