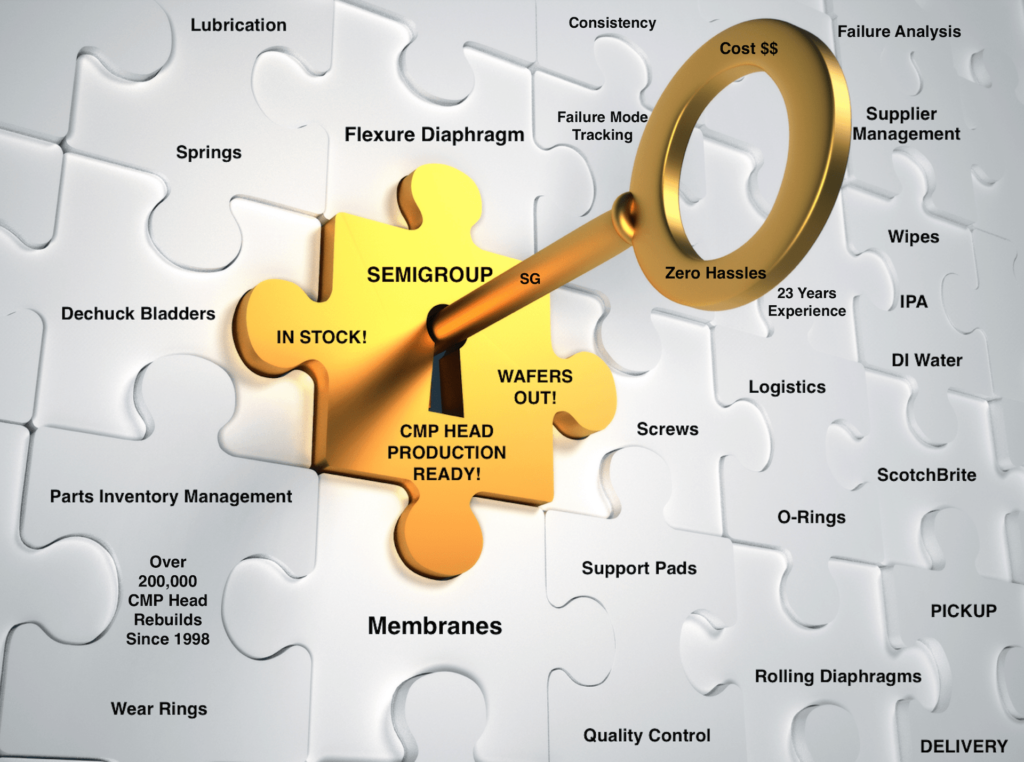

Maximize Your Production with Turnkey CMP Head Refurbishment

Stop losing valuable production time by handling CMP head refurbishment in-house. Each week spent managing these processes translates to missed opportunities for wafer output. Why tie up your team with parts orders and rebuilds when they could focus on manufacturing high-yielding wafers?

Let SemiGroup Handle It.

With our Turnkey CMP Head Rebuilding Service, you gain immediate access to fully refurbished CMP heads, eliminating downtime and enabling uninterrupted production. No waiting weeks for parts or rebuilds—our inventory is stocked and ready to go.

Why Choose SemiGroup?

- Streamline Your Workflow: Reduce parts management, labor, and delays with a ready-to-deploy solution.

- Proven Excellence: Over 27 years and nearly 400,000 CMP heads rebuilt—our experience speaks for itself.

- Faster Turnaround: Skip the 7–14 day wait and get production-ready CMP heads today.

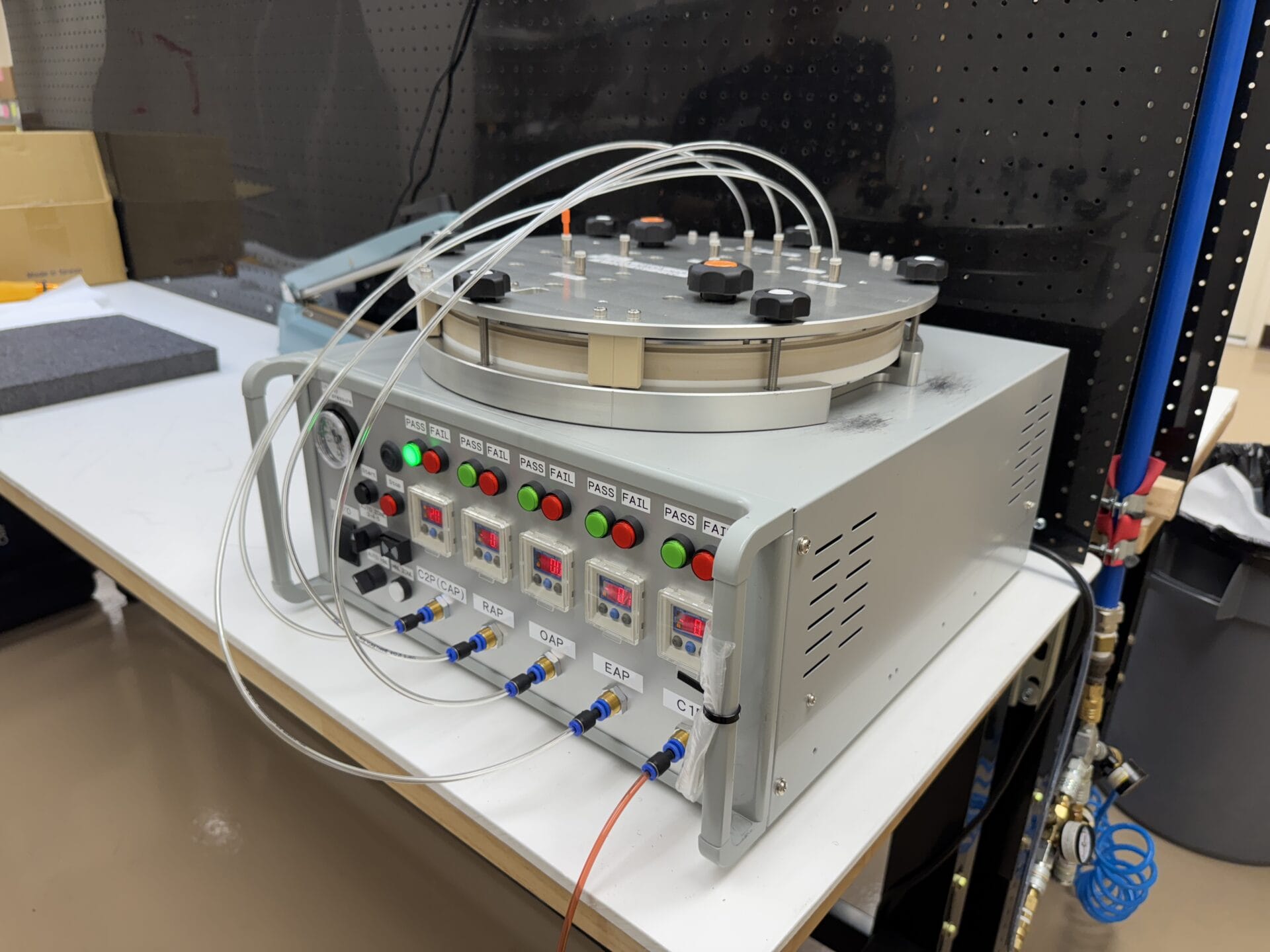

- High-Quality Assurance: Every head is meticulously refurbished with precision and tested rigorously to meet the highest standards.

Precision Matters in CMP Head Rebuilding

Rebuilding critical equipment like the Mirra 200mm Titan 1 CMP Head requires expertise, attention to detail, and quality parts. SemiGroup ensures every refurbished CMP head is ready to meet the demands of semiconductor production, allowing your team to focus on what they do best: moving wafers.

Our Turnkey Service Includes:

- New components including O-rings, sensors, membranes, and more

- Bore and shaft re-lubrication for peak performance

- Rigorous inspections, cleaning, and pressure testing

- Immediate availability—CMP heads ready to ship!

Transparency and Accountability You Can Trust

At SemiGroup, we’re committed to your success. Our Transparency Guarantee ensures you know why your equipment fails and how we fix it. We’re not just another vendor—we’re your partner in achieving seamless production.

SemiGroup: Industry Leaders in Aftermarket Semiconductor Support

Our dedication to quality, longevity, and cost-effective solutions makes us the trusted partner for CMP head refurbishment. Every part we refurbish undergoes a rigorous inspection and testing process, ensuring top performance for your production needs.

Let’s Solve Your Production Challenges

We’re here to help you tackle hard-to-find components and complex refurbishment needs. Whether through a phone or video call, let’s discuss how we can boost your production capacity.

Call us today at 1-888-SEMIGROUP or email parts@semigroup.com to learn more. Visit our online shop to browse parts, request information, or start a new service request.

Featured Service

Our perfected Applied Materials 200mm MIRRA Titan 1 CMP Head Rebuild Service extends equipment life expectancy and maximizes your output. With 27 years of expertise, we ensure your equipment delivers high-yield wafers consistently.

OEM Part Number: 0010-77533

Ready to enhance your production? Request Turnkey CMP Service Now!

Our Industry-Leading Process Includes:

- Visual Inspection & Analysis

- DATA Tracking

- Decontamination & Cleaning

- New O-rings

- New Screws Torqued to Spec.

- New Sensors & New Spring

- New Membrane

- New De-Chuck Bladder

- New Rolling Diaphragm

- New Seal Diaphragm

- New Retaining Wear Ring

- New Membrane Support Plate Pad

- Replacement of air lines and air fittings

- Bore and Gimbal Flexure plate shaft re-lubricated

- Post rebuild clean

- Final Visual inspection

- Final Pressure Test to ensure Functionality